Project 14 PT How efficient is a hydraulic system

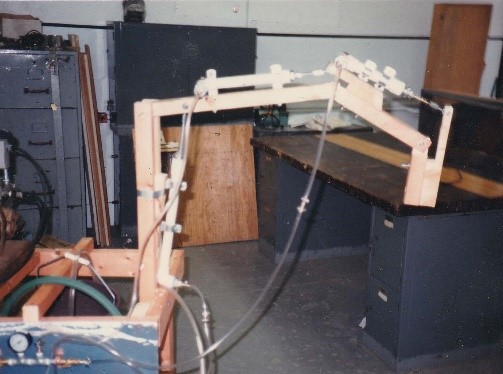

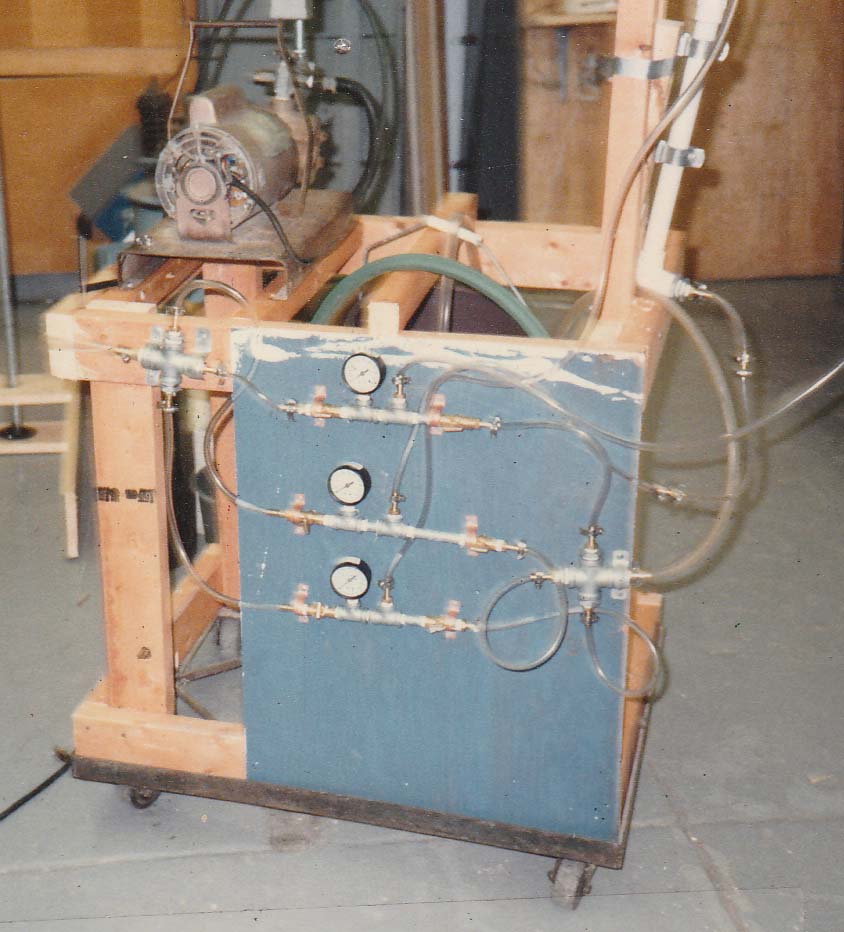

Picture above, left, shows hydraulic pistons we built from starch. Picture above, right shows pressor gages

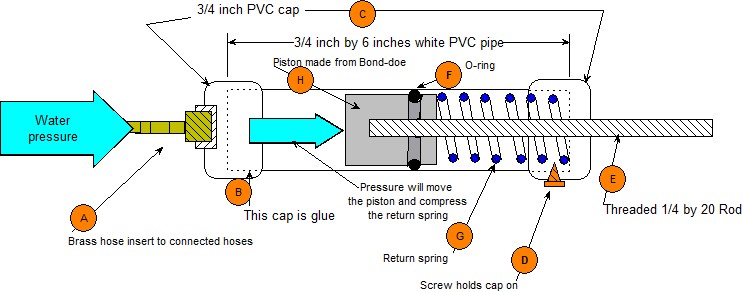

The drawing above the parts table is how a homemade piston is made. The ¾ inch PVC caps on the water side is glued so the water will not leak and the old ring keeps the water from leaking around the piston. As you apply water pressure it moves the piston to the right and as you take pressure off, the return spring will push the piston back where it works like a regular hydraulic piston. .

The drawing above the parts table is how a homemade piston is made. The ¾ inch PVC caps on the water side is glued so the water will not leak and the old ring keeps the water from leaking around the piston. As you apply water pressure it moves the piston to the right and as you take pressure off, the return spring will push the piston back where it works like a regular hydraulic piston. .

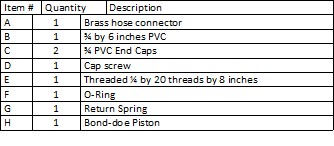

The Picture below shows the hose insert that connects the water line, so you can see the water flow through the clear plastic.pipe.

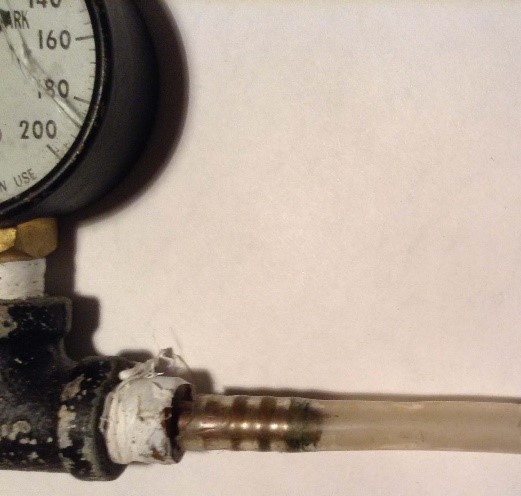

The Picture to the Top left, shows a ¾ inch by 6 inches PVC pipe that is the main cylinder of the piston. There is also one of the end caps in the picture.

The Picture to the Top left, shows a ¾ inch by 6 inches PVC pipe that is the main cylinder of the piston. There is also one of the end caps in the picture.

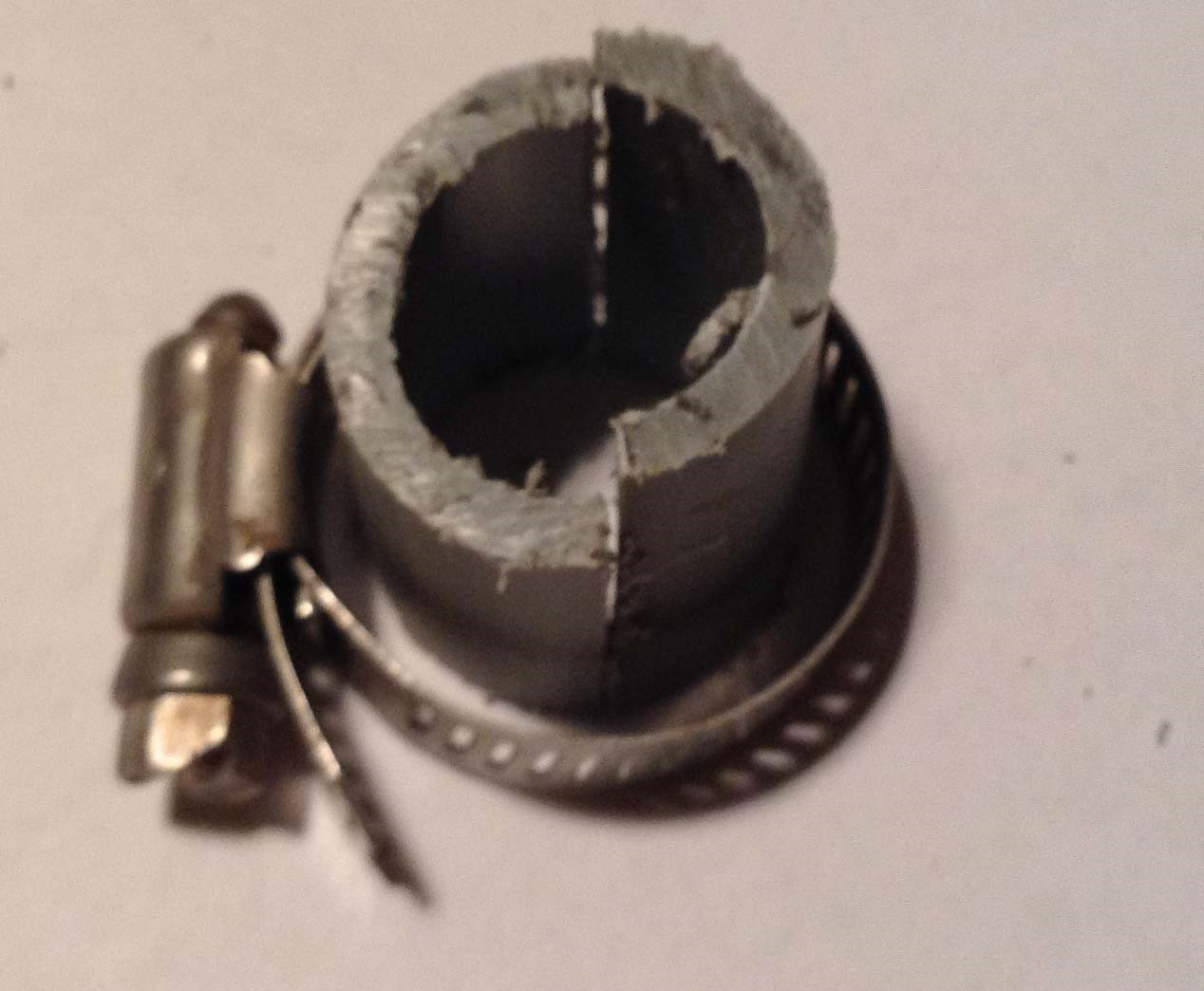

The Picture to top left and Bottom center, is how we made the piston mold. We cut a piece of pipe about an inch to two inches long, cut it in half, put a hose clamp around it to make a mold. Tighten it up and put duct tape on the bottom so that the bond-doe will not run out the bottom. Then we took a ¼ 20 threaded rod by 8 inches and stick it down into the mold before the bond doe start setting up. It usually takes about 10 minutes for the bond-doe to start to set up.

The Picture to top left and Bottom center, is how we made the piston mold. We cut a piece of pipe about an inch to two inches long, cut it in half, put a hose clamp around it to make a mold. Tighten it up and put duct tape on the bottom so that the bond-doe will not run out the bottom. Then we took a ¼ 20 threaded rod by 8 inches and stick it down into the mold before the bond doe start setting up. It usually takes about 10 minutes for the bond-doe to start to set up.

The picture above left show each piston has a gage on it. All the supply for this project 14 can be purchase at a local hardware store. Make sure the O-Ring is larger than the piston and it fit in the groove. At least half the O-Ring need to stick out pass the piston.

The picture above left show each piston has a gage on it. All the supply for this project 14 can be purchase at a local hardware store. Make sure the O-Ring is larger than the piston and it fit in the groove. At least half the O-Ring need to stick out pass the piston.

You need a razor blade and a tube of Super Glue. You cut the O-Ring and put it around in the groove and mark it to fit. Cut it and glue that together and it is perfect for this type of project and start rolling it over the top of the piston until it falls into the grooves. That will block the water from coming into the return spring chamber.

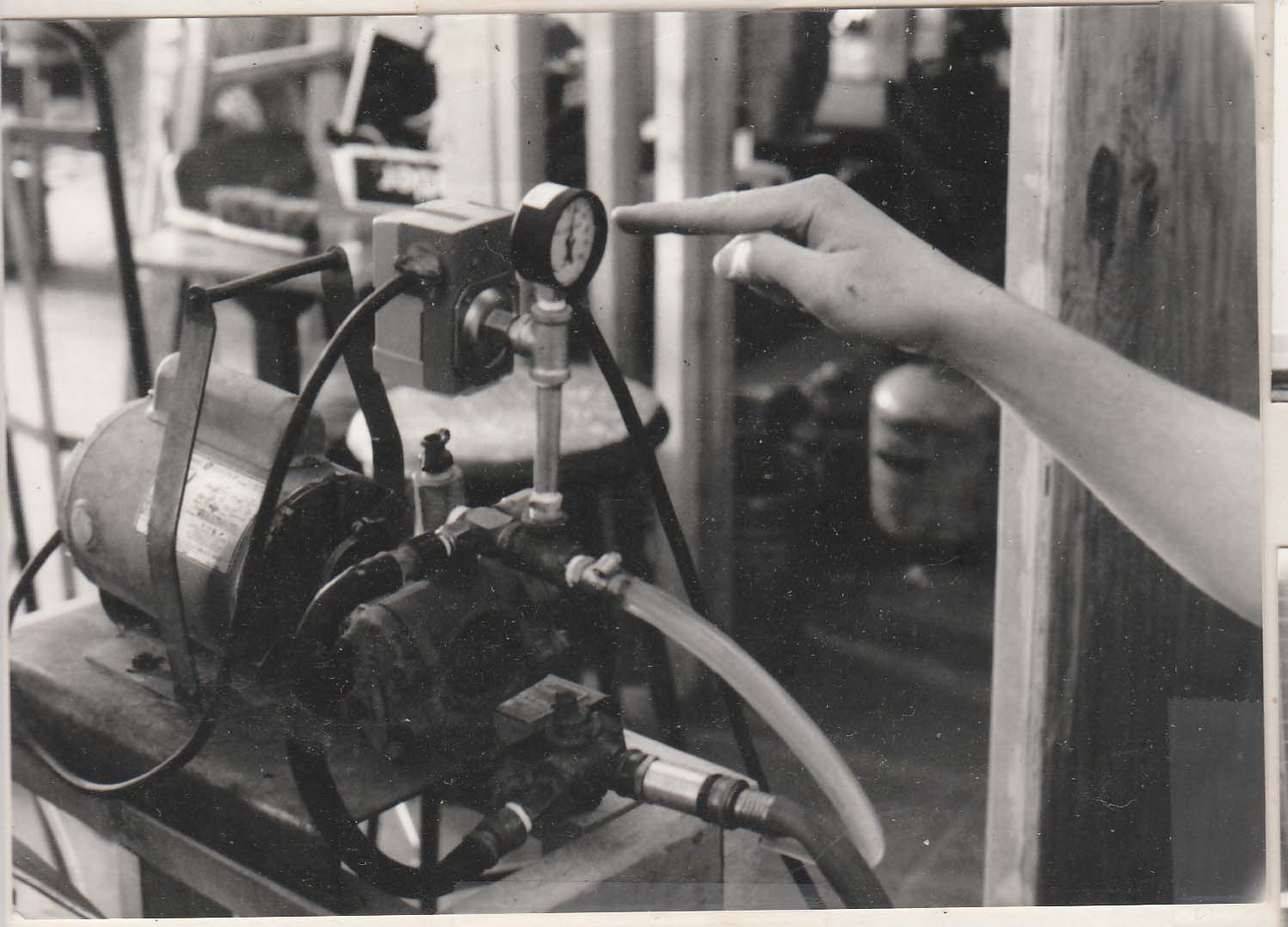

There is a water pump on top of the box, with a main pressure gauges to read the total pressure. Picture 20 there is a pressure gage on each pistons. We can calculate how much Work it takes to measure the efficient of the system. There is a pressure regulator to keep the pressure from getting to high.

There is a water pump on top of the box, with a main pressure gauges to read the total pressure. Picture 20 there is a pressure gage on each pistons. We can calculate how much Work it takes to measure the efficient of the system. There is a pressure regulator to keep the pressure from getting to high.