How I acquire my teaching career at SIU-C

I started teaching in 1979 when I was running my own business. I purchase Mosely Supply in1975. I changed the name of the store to Sipes’ Supply. The store was in West Frankfort Illinois, Heights. I was running 3 business out of this store. Sipes’ Supply, Sipes’ sheet metal and Sipes’ Electric INC.

I had three electricians working at a local coal mines. My job was running supply to the electricians and supervising their work.

I was doing alright until Jimmy Carter got elected to president of the United States. Everything fell apart, but during that time there was not a whole lot to do because the business was slowing down.

I was on a technology board at West Frankfort High School. They would meet once a month with Ron Smith, which was one of my teachers when I was in high school. We would go to a meeting once a month at the high school. He was wanting to get an Electronics Program in the high school.

A year later I got a call from a professor at (Southern Illinois University at Carbondale) SIU-C and he wanted to know if I would teach an Electronics class for four weeks, because the guy they hired did not show up, so I said “sure” and starting teaching.

The teaching hours was 18 hours a week in the class room, 4 hours a week in my office. I had to be on campus 22 hours a week. The rest of the time was my time. I started teaching and when the four weeks came around, I went to look up the dean that asked me to teach the classes. He was nowhere to be found. Evidently, I went to the secretary of this dean and she had a stack of papers on her desk. She was trying to get caught up, because she just started this job, this semester. So after a couple of days, they went through them and found a sheet to put me on the payroll. I took it over to payroll and I got four weeks’ pay and thought “this is not bad at all”.

I found out that the Dean was on a sabbatical to China and would not be back until the end of the semester. Another dean asked me if I would teach next semester and I said “sure” so I was there for six years. I started working on a Bachelor Degree, because SIU-C would pay my tuition since I was an employee of the University. I was allowed to take 6 credit during the spring and fall semester. I could take up to 14 credit hours during the summer semester.

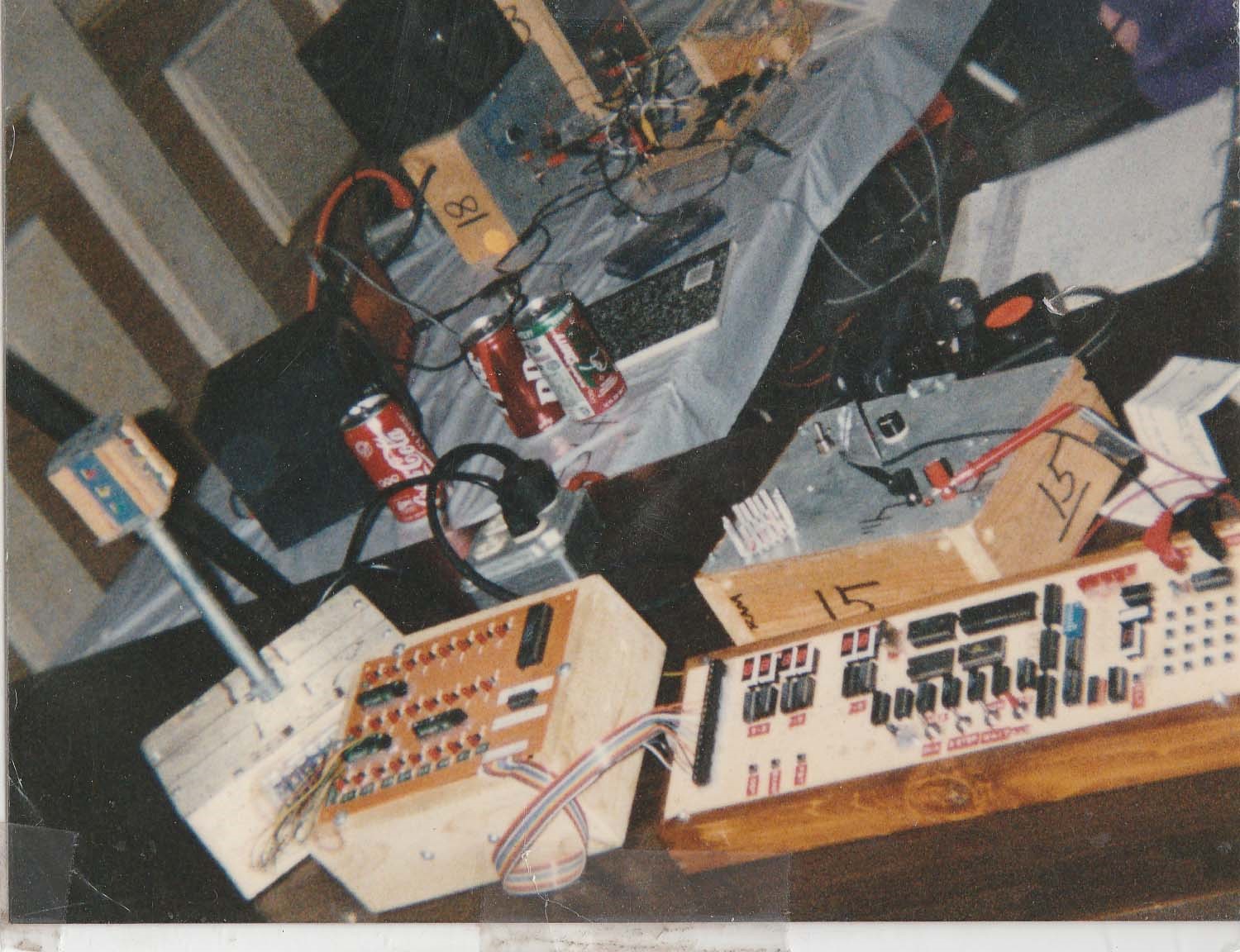

I did that one summer and I learned how to build an intergraded computer circuit from chip level with 8085 processors

. From the processor to control chips to hexadecimal coded key board. You inter your codes in the key board to the processor and the processor would output to 8 LED in binary code. To complete the project.

They hired me on an Associate in Technology Degree in Electronics which was two years of college with 60 credits. All my junior year credits were from work experience. This program was called the Capstone Program. I received 30 credit through this program.

I needed 30 credits for my senior year. I took 9 credits general studies and some more electronic credits and in 3 years, I needed 1 general studies credit for my Bachelor Degree.

How I acquire my teaching career at West Frankfort High School

My business was terrible so I went to the high school Principal, Mr. Patton, and asked him what the chances of getting hired. He said they are real good if you do not get your Bachelor Degree yet. He said we can hire you for $10,000 dollars for 4 hours in the morning the first school year. Then you can get your Bachelor Degree.

I already told SIU-C that I would teach next year. That was a busy year. It was a little rough as I was working 50 to 60 hours a week. Teaching at the high school from 8 AM to noon, Monday to Friday and at SIU-C from 1 PM to 5 PM, Monday to Thursday.

I was offered a weekend Electronics program for 2 years at SIU-C. It would be Saturday and Sunday for 8 hours each day and Wednesday night for 4 hours.

The reason I took both jobs was my pay at SIU-C had doubled because of the Bachelor Degree. The pay at the high school went from $10,000 dollars too $27,000. For a school year and my business was terrible and I had a lot of bills to pay. I paid most of the bills off and closed the doors. After 2 years, I finally gave up all my work at SIU.

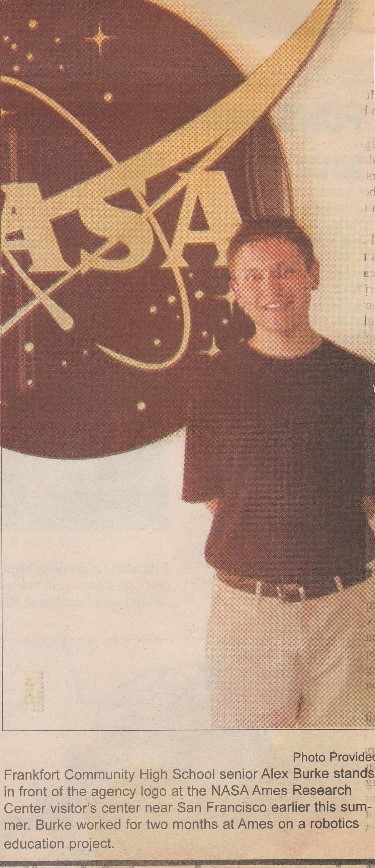

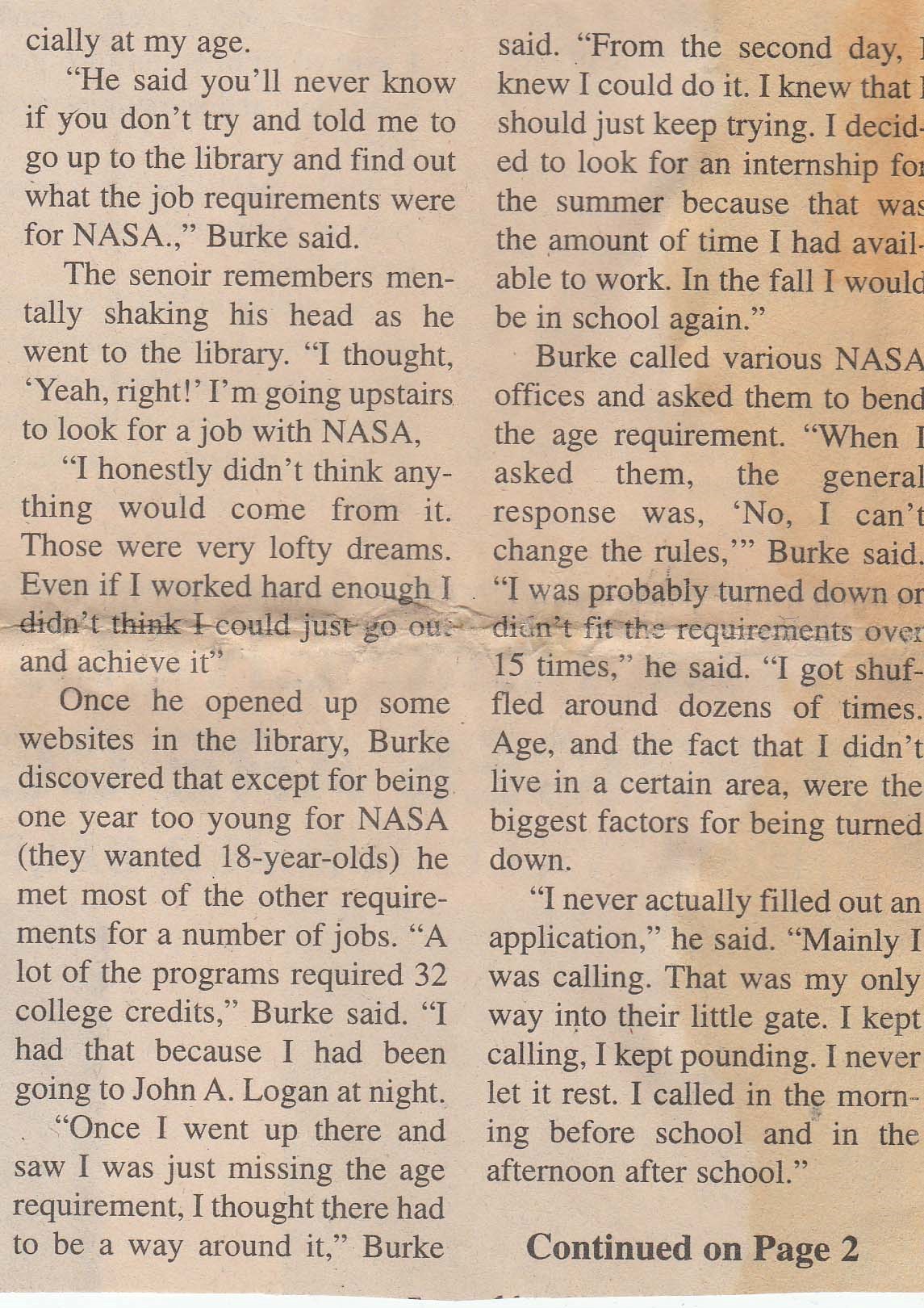

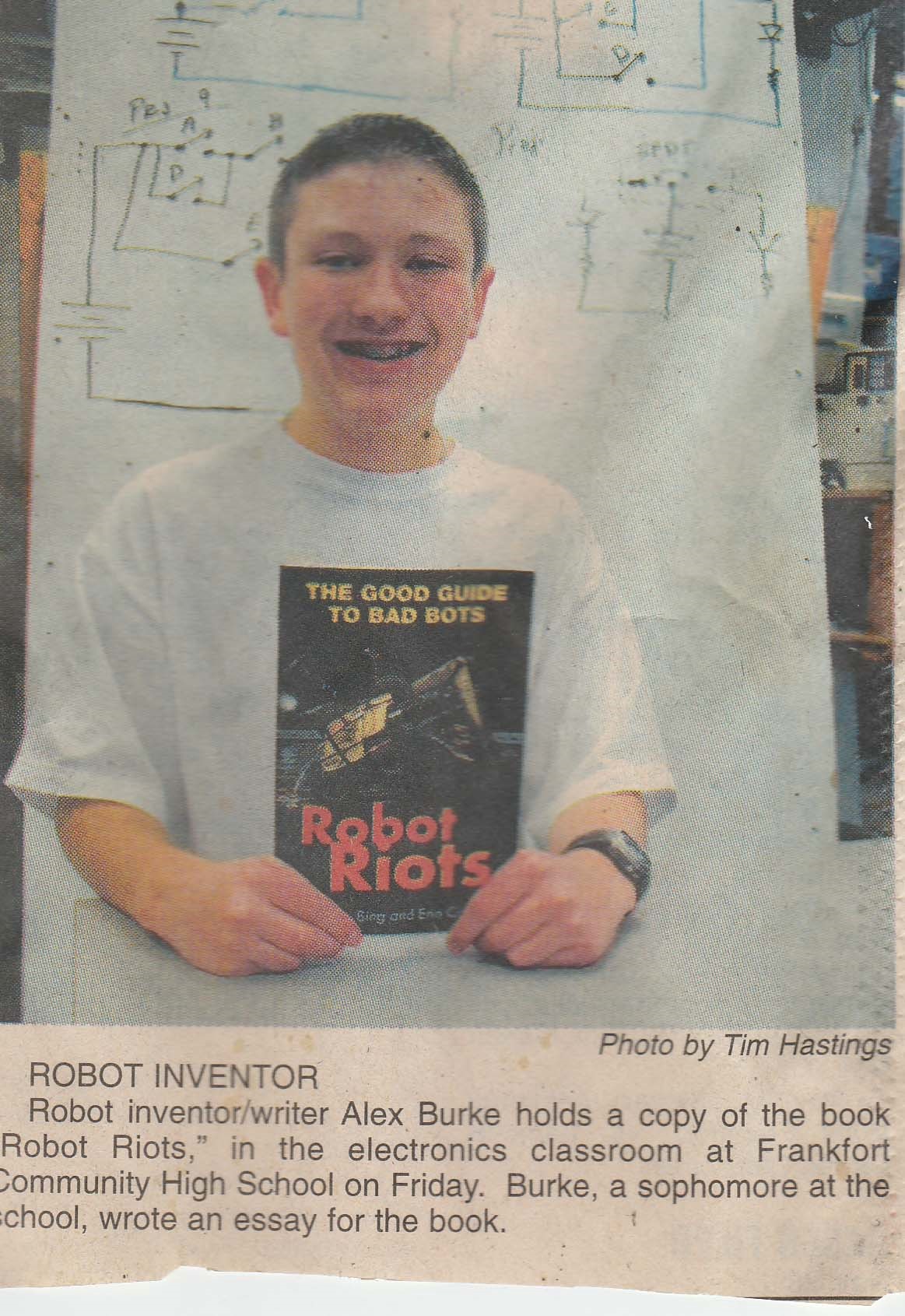

Project 1…Alex Burke @.NASA

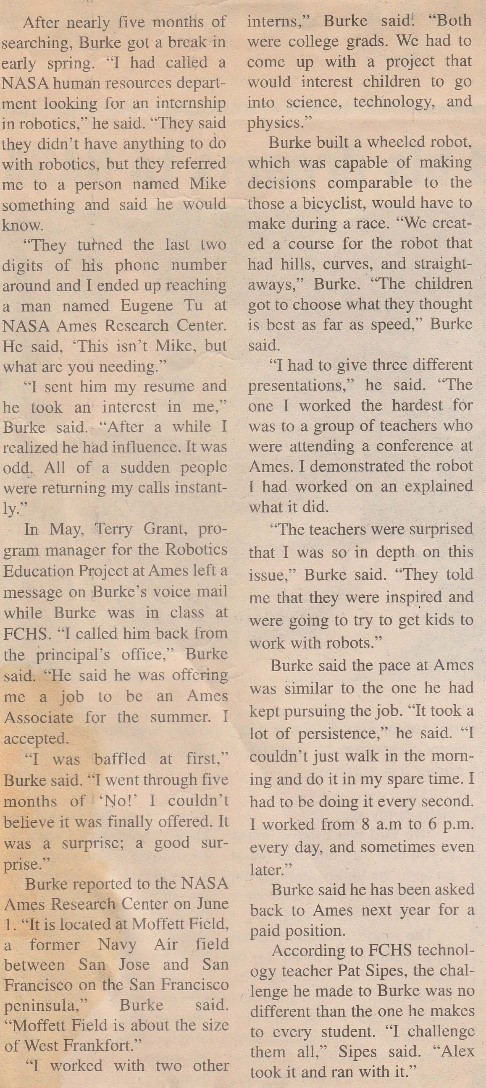

Alex Burke, is a very brilliant student and loved doing robotics project and interfacing the computer to project. He would write the programs to control project

He acquire an internship to go to NASA Ames Research Center in California.

He came back his senior year with all kinds of robots knowledge. Everything went extremely well. He stayed out there for 10 weeks and learned a whole lot about, if he wanted to work for NASA.

When Alex Burke works for Wallace Electrical Systems. He design and built a small computer circuit board to monitor the emergency stop switch. These main belt are usually 1,000 to 12,000 feet.

If the belt quits, a miner would have to walk the full length of the main belt to find out what happened. The miner is looking for ceiling caved in or if the belt broke or if something got in the belt. Before they can turn the power back. Alex put a computer chip every 1,000 feet and a signal on the DC line that ran through the existing emergency stop system.

Most belt line in the coal mines runs a 2 wire, 24 volt DC emergency stop system. These switch were put ever 1,000 feet along the total length of the line’

Alex powered up that small computer by putting them across the 24 volt, DC voltage line. These small computers are installed in the emergency stop button boxes. Each small computer inject a 5 volt signal on top of the 24 volt DC line.

The small computer monitor each emergency stop switch to see if it open or close. If the switch is open it send a signal to the main computer and tell it to lock out the main belt line. The main computer knows the location of the open switch and tell the operator. If the switch is close then the small computer tell the main computer ever thing is ok at this location. Each location is monitor ever 3 second. The belt cannot be turn on until the main computer operator clears all the small computer.

Each small computer would monitor 500 feet down the line and 500 feet up the line.

Project 2….Machine to box CD & DVD

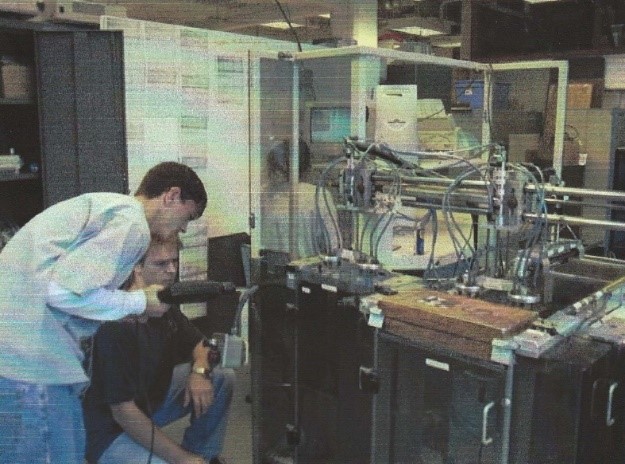

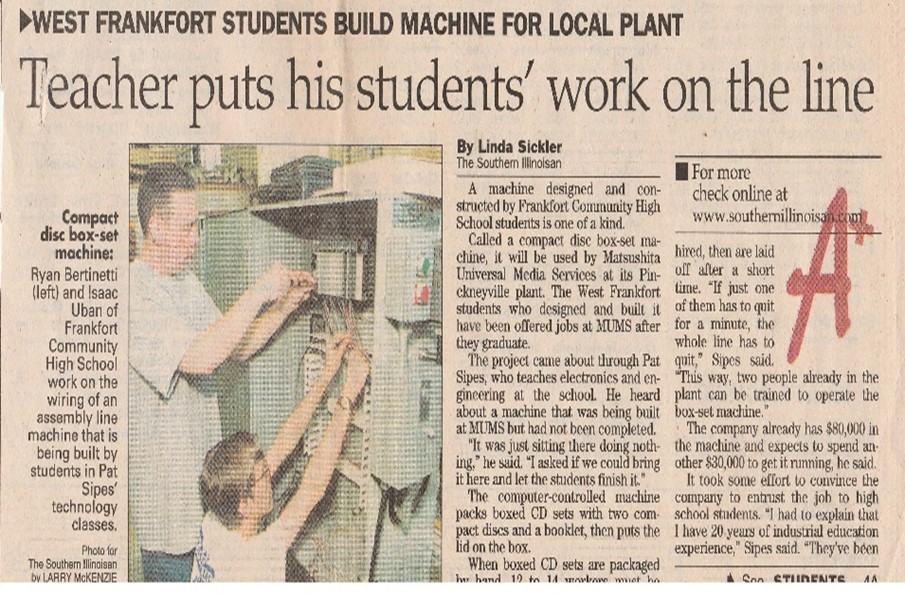

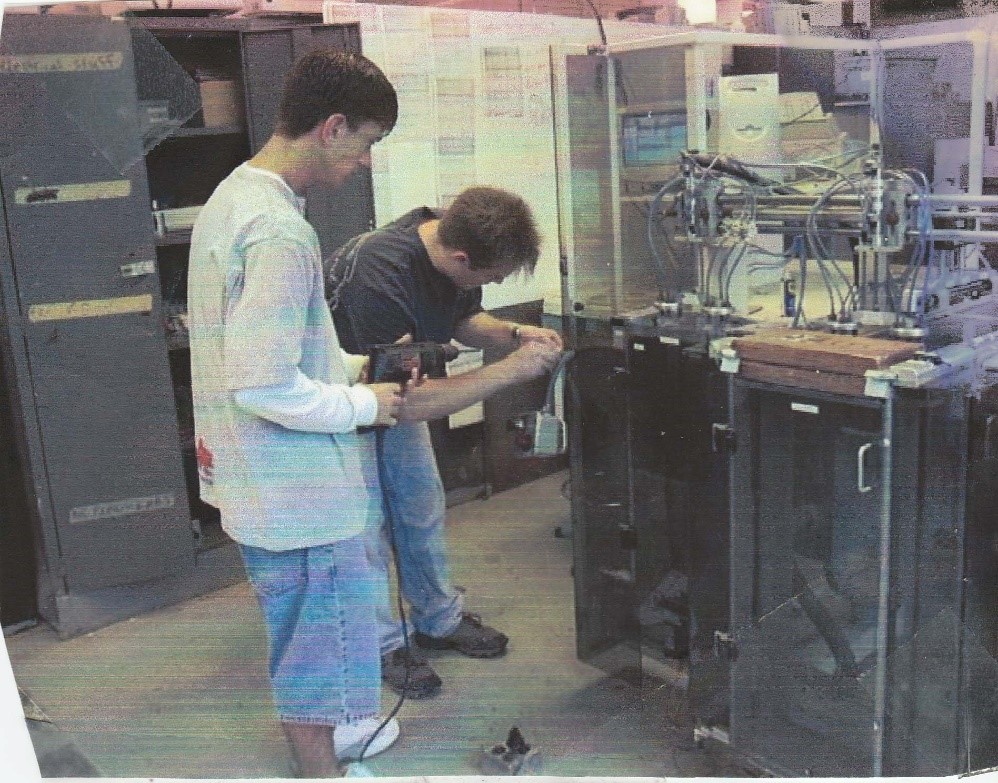

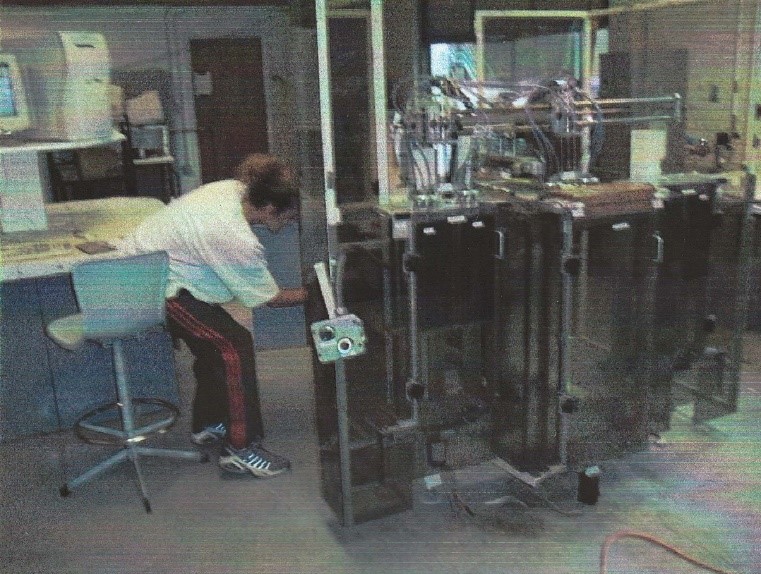

Project 2, is a machine that boxes up CDs and DVDs and bring them down an assembly line and put your CDs in a box, first it would have the machine lift off the lid of the box and come down on a conveyor belt and an air vacuum arm would come out and pick up a CD and drop it in the box and it would go to the next

Project 2, is a machine that boxes up CDs and DVDs and bring them down an assembly line and put your CDs in a box, first it would have the machine lift off the lid of the box and come down on a conveyor belt and an air vacuum arm would come out and pick up a CD and drop it in the box and it would go to the next station and drop in a book and then it would go to the next station where it would pick up the lid and put it back on the CD box and then run it through a machine that wraps it in cellophane and ready to go to the store.

station and drop in a book and then it would go to the next station where it would pick up the lid and put it back on the CD box and then run it through a machine that wraps it in cellophane and ready to go to the store.

You can see the two students Garrett Collier and Clarice Chick above. Clarice is writing a program for the developer machine and Collier is inspecting the machine to see if it is running smooth.

they are getting ready to mount a power box, what it is, an emergency stop. It stop the machine if something jams up.

they are getting ready to mount a power box, what it is, an emergency stop. It stop the machine if something jams up.

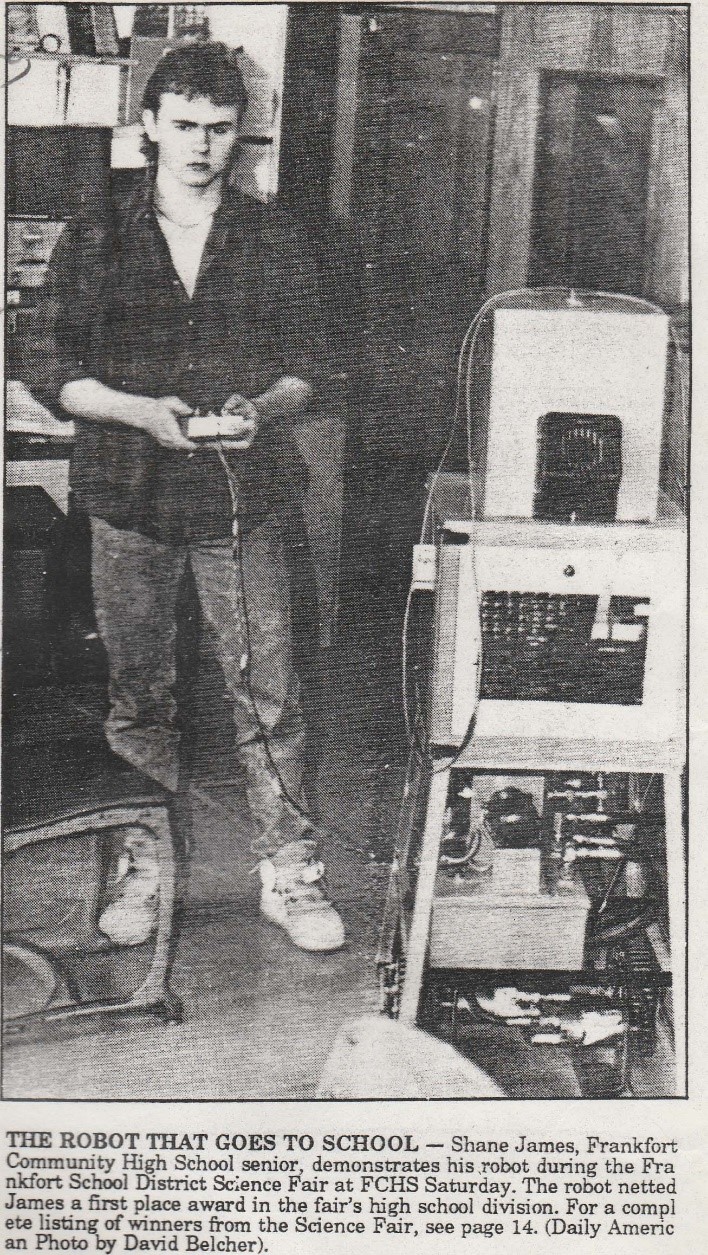

Project 3 Shane James

Shane James. He is one of the most intelligent students that I had the privilege to teach. He is good natured, and worked hard at home and school. He excel in everything he does.

Shane James. He is one of the most intelligent students that I had the privilege to teach. He is good natured, and worked hard at home and school. He excel in everything he does.

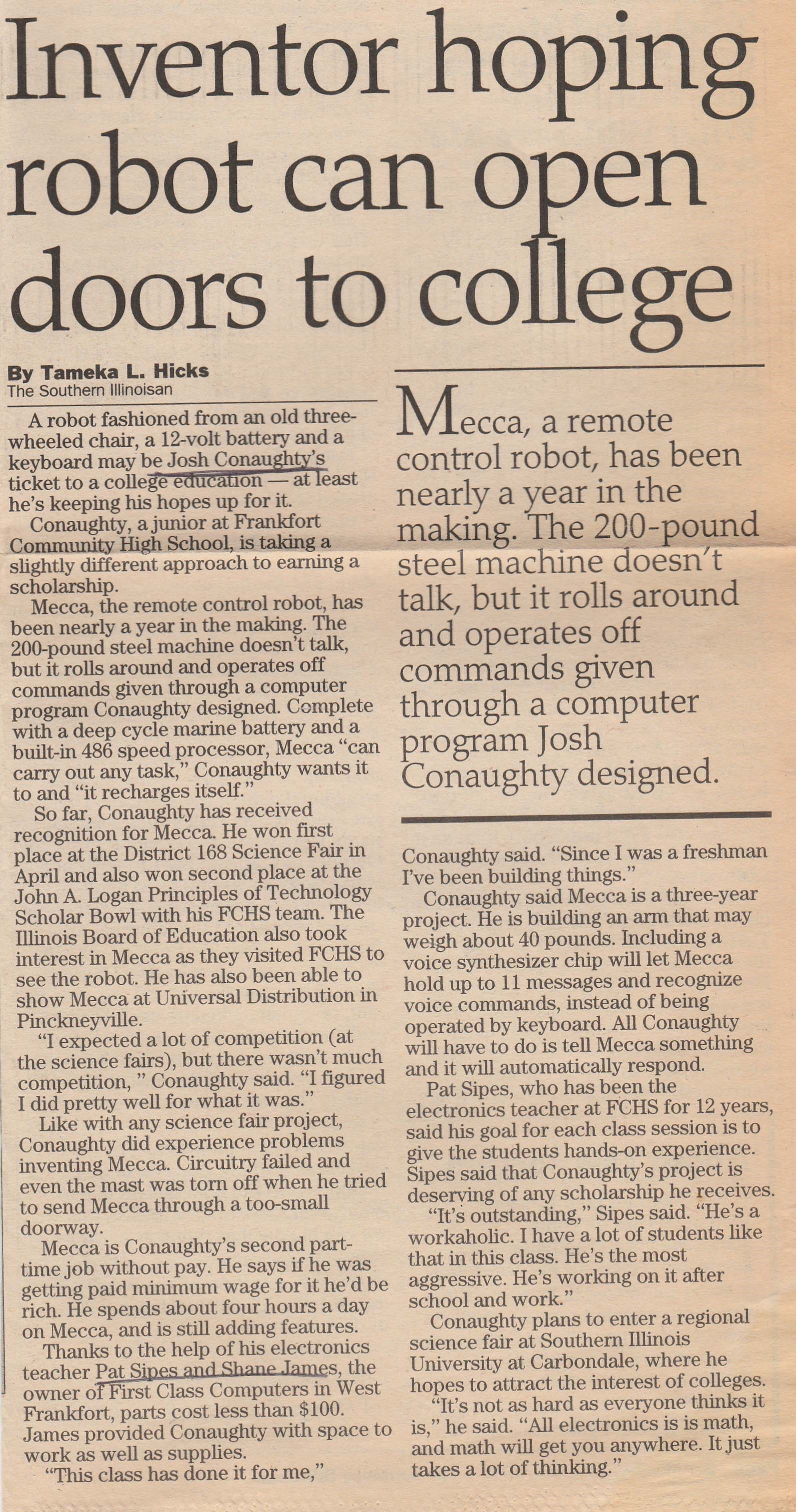

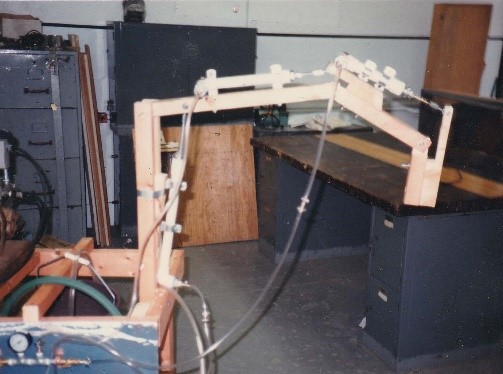

He works for Oracle. He is way up in middle management and I see him going higher in the next 5 years. One outstanding project he did was a robot. That is picture #1. All the electronics, switches and wiring were built by him. His dad was a welder and he help Shane build the robot frame work. The robot had a 12 volt battery which power the

12 volt hydraulic pump and the computer chips. He could move it forward, reverse, right or left. The computer he used was a small 8 bit 8085 micro computer chip. He wrote the program in machine language.

He had a chip that was made for the automotive companies which had a translator circuit, voice to switches control. The switch controller would control 5 hydraulic electric value that turn both wheels ON or OFF. He could tell the robot to STOP, GO FORWORD, GO REVERSE TURN RIGHT and TURN LEFT.

12 volt hydraulic pump and the computer chips. He could move it forward, reverse, right or left. The computer he used was a small 8 bit 8085 micro computer chip. He wrote the program in machine language.

He had a chip that was made for the automotive companies which had a translator circuit, voice to switches control. The switch controller would control 5 hydraulic electric value that turn both wheels ON or OFF. He could tell the robot to STOP, GO FORWORD, GO REVERSE TURN RIGHT and TURN LEFT.

It was a fairly powerful machine. It could move anything because of the size of the pump motor. It had to have a big battery to power up everything. The motor for the pump was a 12 volt motor and that took up a lot the space in the bottom of the robot.

It was really outstanding, project. He won a bunch of prizes, I had him put all the drawing into a portfolio. Which help him launched his career in electronics and computer after he graduated from West Frankfort High School and John A Logan CollegeIt was a fairly powerful machine. It could move anything because of the size of the pump motor. It had to have a big battery to power up everything. The motor for the pump was a 12 volt motor and that took up a lot the space in the bottom of the robot.

It was really outstanding, project. He won a bunch of prizes, I had him put all the drawing into a portfolio. Which help him launched his career in electronics and computer after he graduated from West Frankfort High School and John A Logan CollegeIt was a fairly powerful machine. It could move anything because of the size of the pump motor. It had to have a big battery to power up everything. The motor for the pump was a 12 volt motor and that took up a lot the space in the bottom of the robot.

It was really outstanding, project. He won a bunch of prizes, I had him put all the drawing into a portfolio. Which help him launched his career in electronics and computer after he graduated from West Frankfort High School and John A Logan College It was a fairly powerful machine. It could move anything because of the size of the pump motor. It had to have a big battery to power up everything. The motor for the pump was a 12 volt motor and that took up a lot the space in the bottom of the robot.

It was really outstanding, project. He won a bunch of prizes, I had him put all the drawing into a portfolio. Which help him launched his career in electronics and computer after he graduated from West Frankfort High School and John A Logan Colleg

It was a fairly powerful machine. It could move anything because of the size of the pump motor. It had to have a big battery to power up everything. The motor for the pump was a 12 volt motor and that took up a lot the space in the bottom of the robot. He went back to school and moved up in every new job he had. I do not have his resume but I bet it is very impressive

.

e.

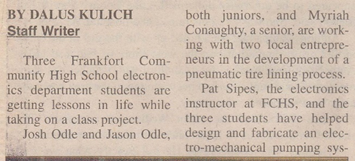

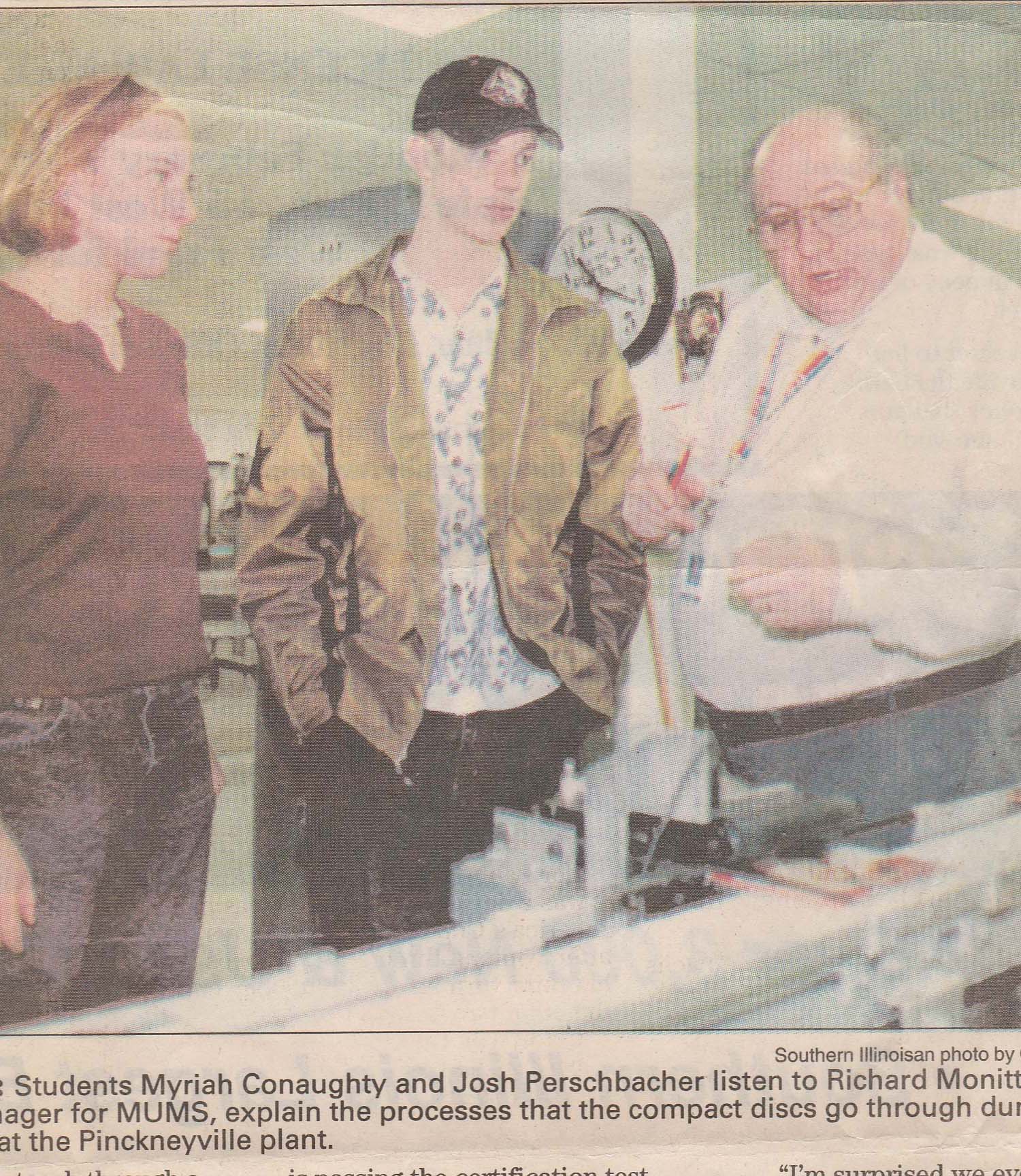

Project 4 Myria Conaughty, Josh Odle and Jason Odle

z

z

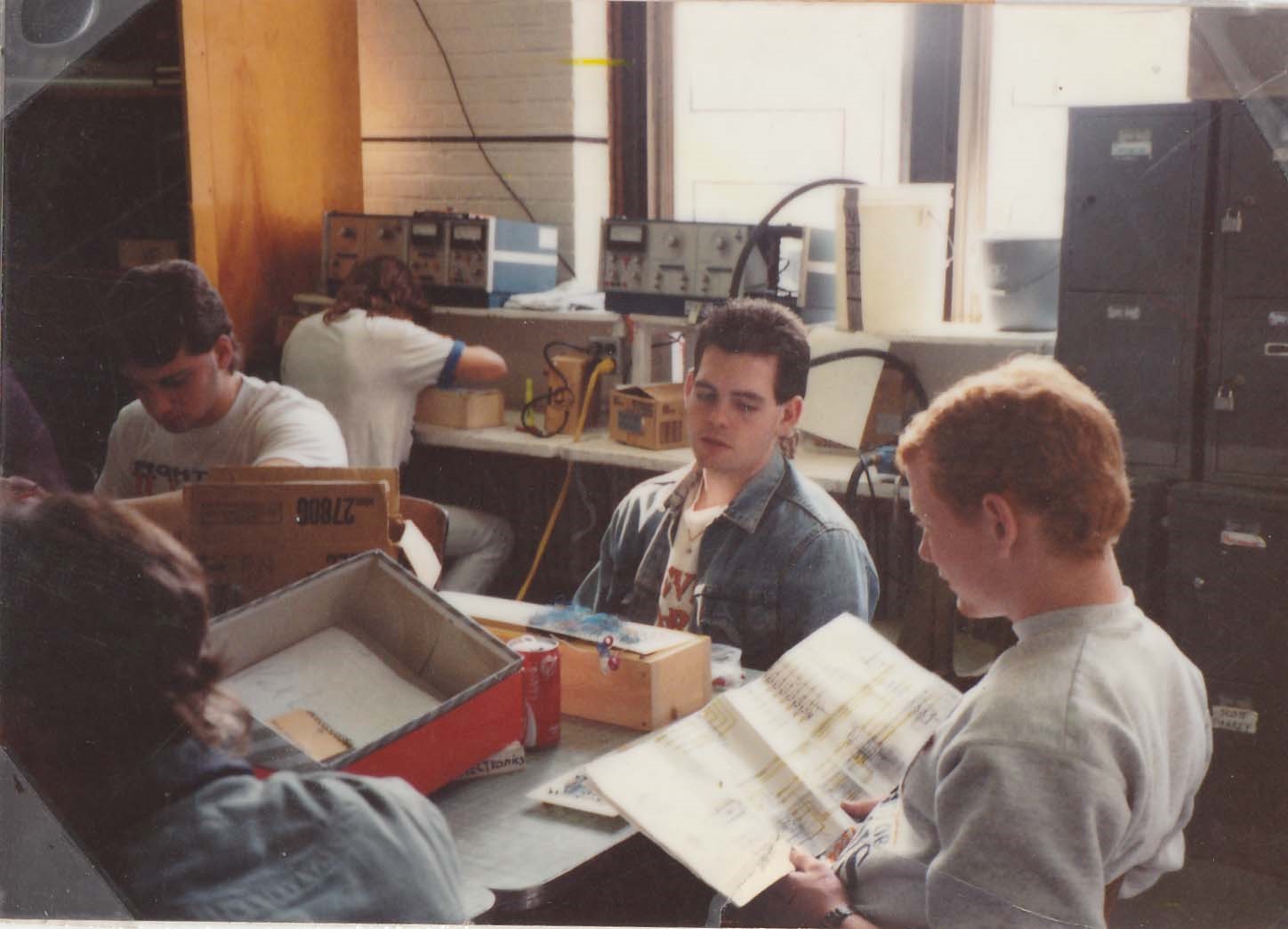

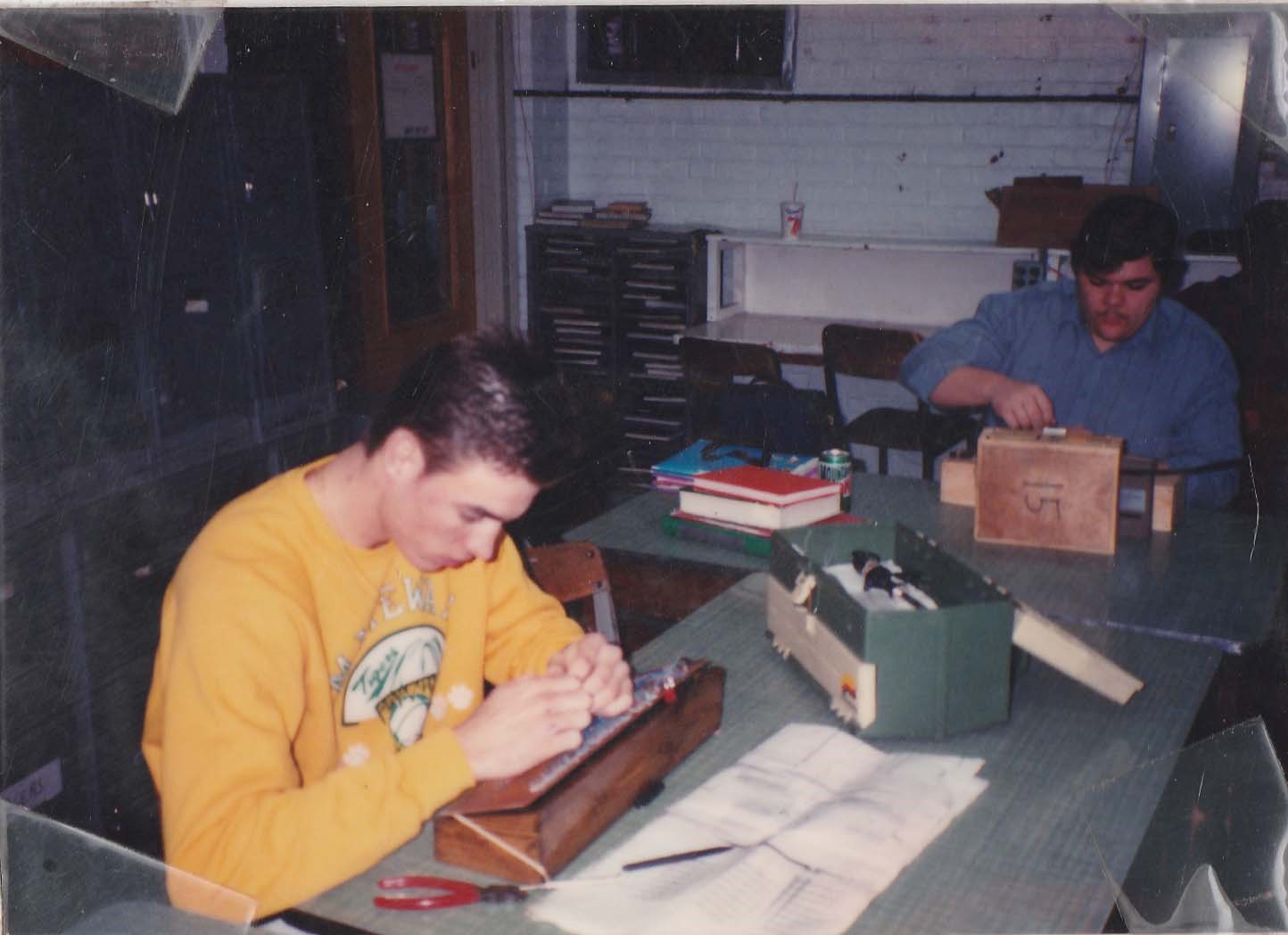

Project 6 Aaron Wolf & Computer Four Bit

I had my advance electronic class build an intergraded computer circuit from chip level with a Four Bit processor. From the processor to a control chip to hexadecimal coded key board. You inter your codes in the key board to the processor and the processor would output to 4 LED in binary code. To complete the project each student had to write the program in machine language then have the computer RUN the program.

I had my advance electronic class build an intergraded computer circuit from chip level with a Four Bit processor. From the processor to a control chip to hexadecimal coded key board. You inter your codes in the key board to the processor and the processor would output to 4 LED in binary code. To complete the project each student had to write the program in machine language then have the computer RUN the program.

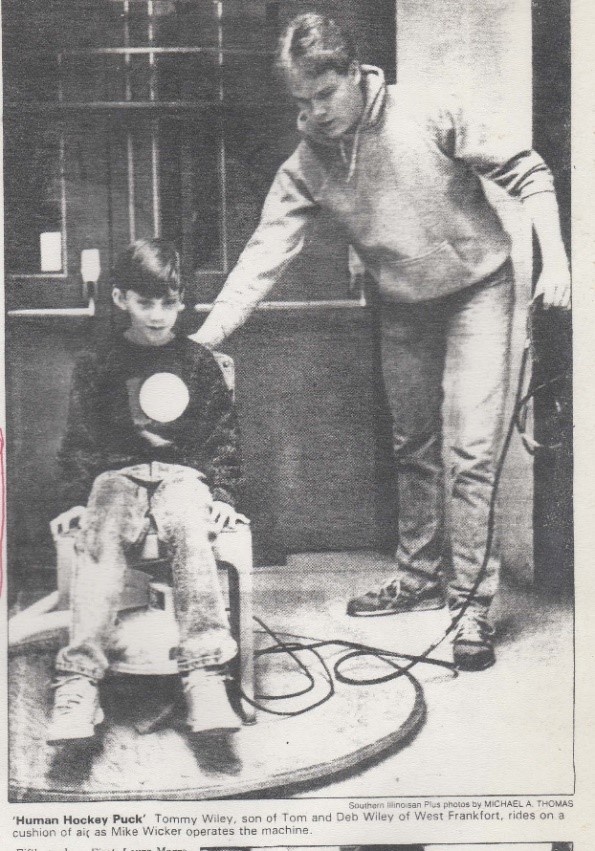

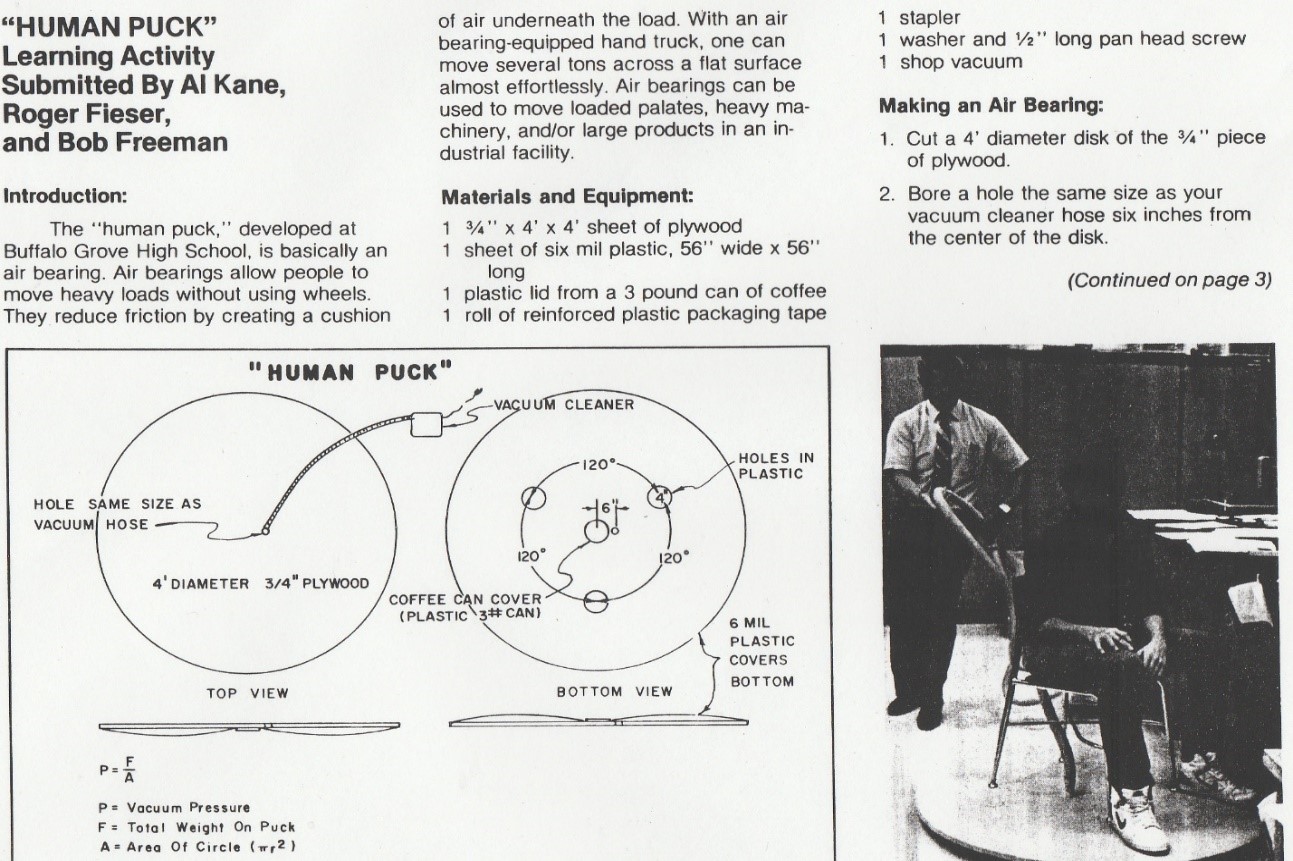

Project 5 Mike Wicker & Human Hockey Puck

This picture is how the Hovercraft worked. We bought a sheet of ¾ inch plywood. Cut out a 4 foot circle. We put plastic on the bottom and cut three holes in the plastic. Turned it face down on the floor and put an ordinary shop vacuum in the hole in the center and blew air in. It would rise up on a cushion of air and you could move the student around to everywhere you wanted to go. It was a lot of fun.

Project 7 Ciar Chick and her portolio

Project 12

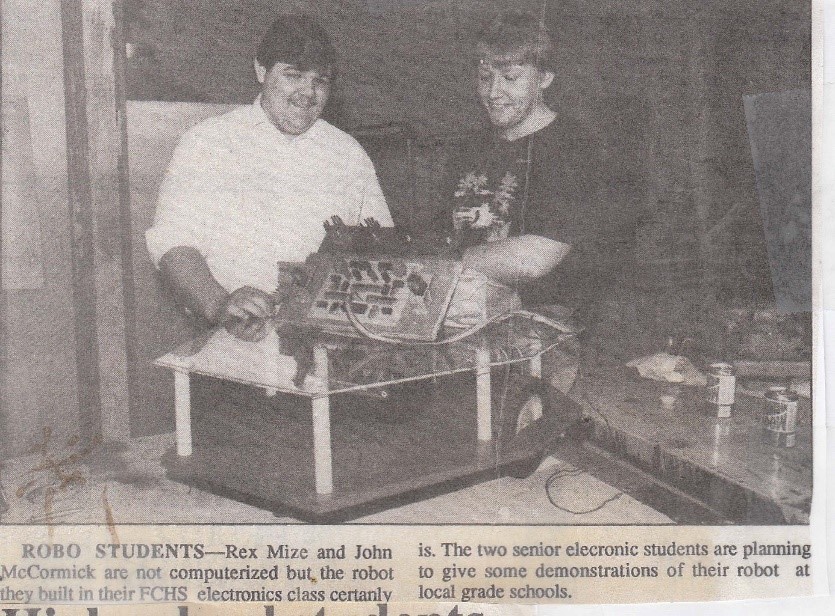

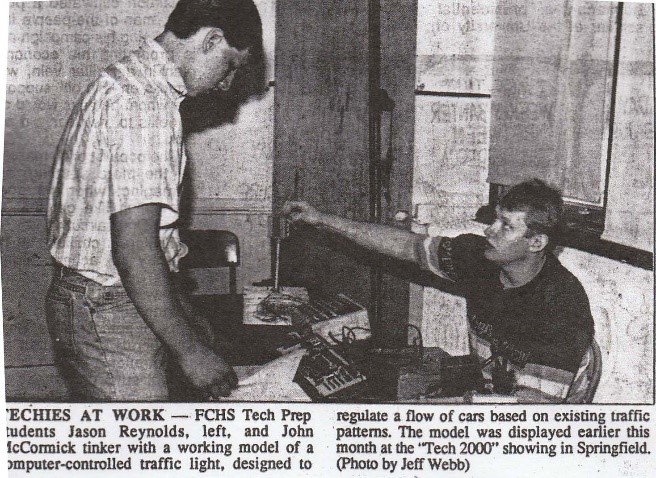

Project 8 Mc Cormick and Myez ROBOT

Picture 10 is Rex Myes and John McCormick. John was one of these students who is very intelligent. Did a lot of work at home and building his 8085 computer. Rex was very good a fabrication and he helped him design a robot and ran it off a 12 volt battery and when it would running into walls. It would back up, and then go, right or left. They had an umbilical cord hooked up to it so it would not get away from him. They did a outstanding job.

Picture 10 is Rex Myes and John McCormick. John was one of these students who is very intelligent. Did a lot of work at home and building his 8085 computer. Rex was very good a fabrication and he helped him design a robot and ran it off a 12 volt battery and when it would running into walls. It would back up, and then go, right or left. They had an umbilical cord hooked up to it so it would not get away from him. They did a outstanding job.Project 9 Dale Kinneck and wind speed meter

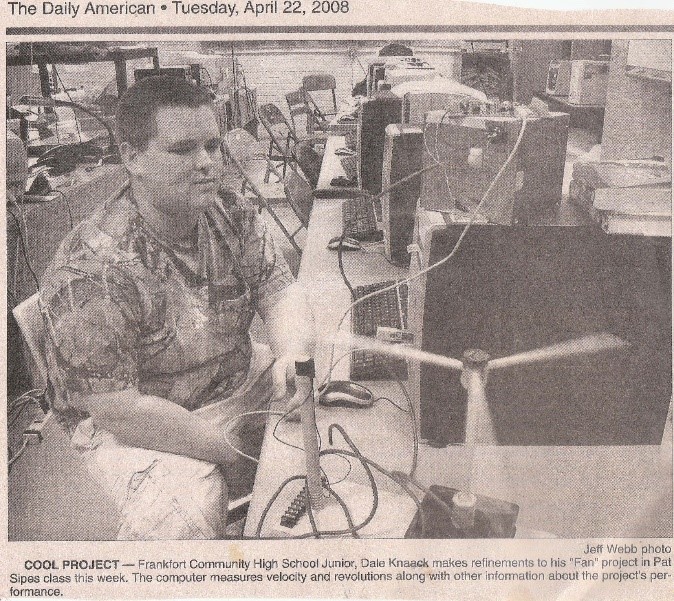

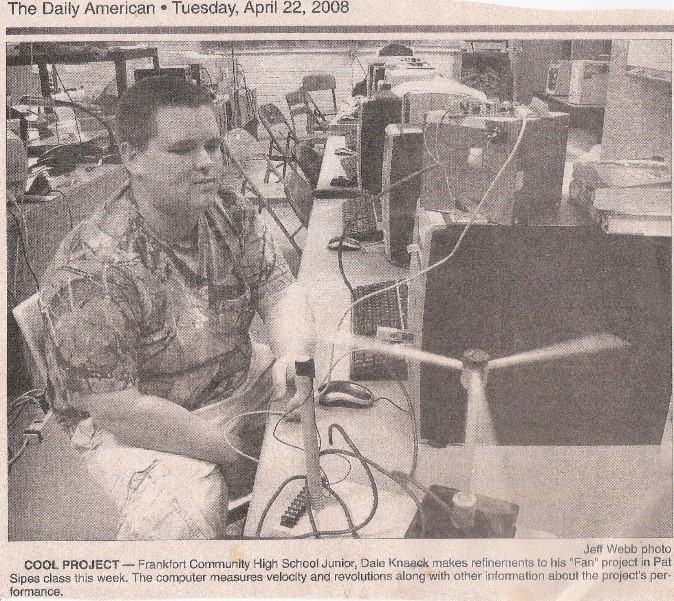

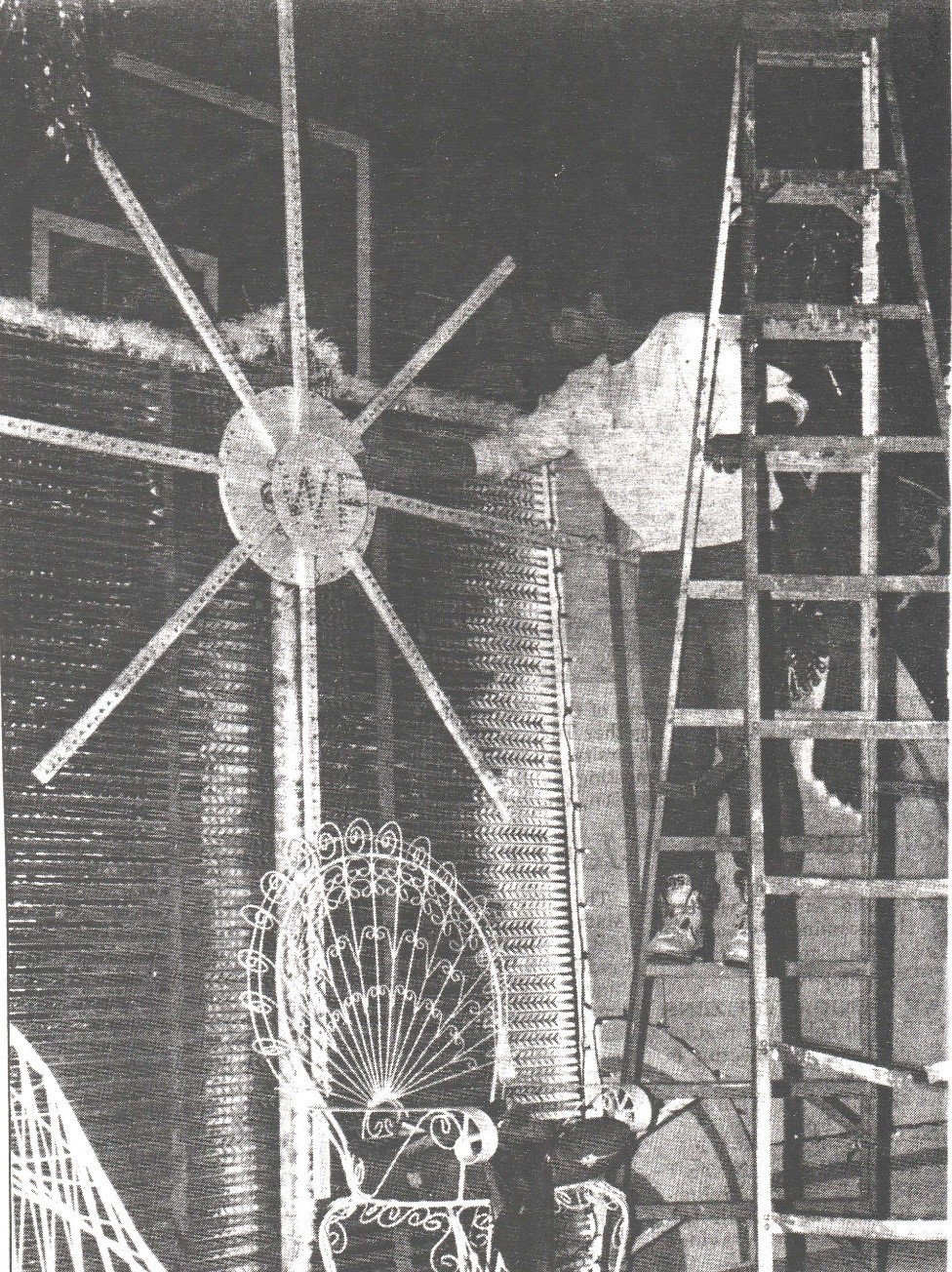

Project 9 Dale Kinneck & Wind Speed Meter.

Dale Kinneck. He is an outstanding student. He loved computers. He read about computers. I showed him how to build an interface that would hook up to a PC through a USB port. He built a windmill or a wind speed gauge which is shown in picture above. There was a magnet on one end of the fan blade and the magnet would trip a switch. The computer would count how many times the switch tripped in 10 seconds and then calculated the wind speed by the diameter of the blades and how fast it would travel at the end of the blades.

Dale Kinneck. He is an outstanding student. He loved computers. He read about computers. I showed him how to build an interface that would hook up to a PC through a USB port. He built a windmill or a wind speed gauge which is shown in picture above. There was a magnet on one end of the fan blade and the magnet would trip a switch. The computer would count how many times the switch tripped in 10 seconds and then calculated the wind speed by the diameter of the blades and how fast it would travel at the end of the blades.

It was a very impressive project.

Project 10

Picture above is Jason Reynolds and John McCormick. . John built an 8085 processor then he wired a miniature traffic light circuit by using red, yellow and green LED. He drawn out an intersection on a wood box. The light had four outputs and the computer would control them depending on how many cars were at each intersection. He had a switch on the bottom of the box that acted like a detector that they have in the roads. It worked very well. They took it to Springfield to the capital building and show how they built all the stuff from scratch using the 8085 processor chip and the project went very well. He is doing great these days working for a big power plant in Illinois.

Project 11

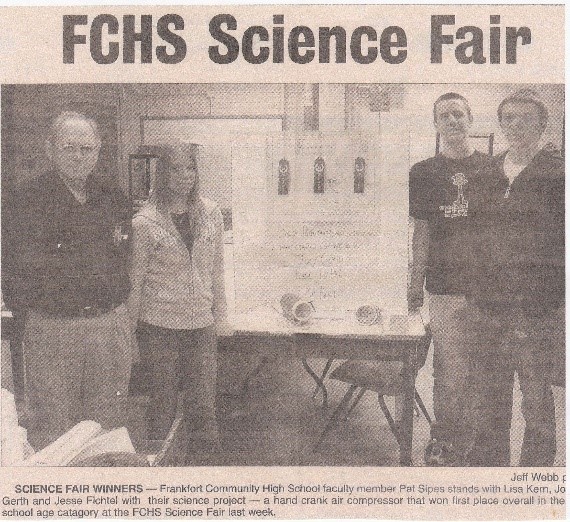

The three students in picture below, build a pressure pump that would build up pressure. They designed it on a CAD system, then they made the pistons, the push robs, crank and the sleeve for the pistons, a cap for the intake air and a cap for the out take air and it would build up pressure that you basically could fill up a balloon with. It was not very strong but it did pretty good job. All material were purchase from a hard ware store. I was really impressed with their talent to get the job. They won first place.

Project 12

Project 13 Josh Conaughty and MECCA

Josh Conaughty is really another outstanding student. He built a robot called MECCA. It ran on a 12 volt and 5 volt system. MECCA is controlled with an 8085 microprocessor.

Josh Conaughty is really another outstanding student. He built a robot called MECCA. It ran on a 12 volt and 5 volt system. MECCA is controlled with an 8085 microprocessor.

The sensor at the top of the robot send data to the 8085 microprocessor about its location. If it see something in its path the sensor will tell the robot to stop. Then the robot will turn 90 degrees to the right, check the sensor to see if there is anything in front of it. If there nothing in front it will preceding on the new path. If there is something in its path, it will turn right again.

This robot was featured on Channel 3. It was an A+ program they had in the newspaper and Channel 3 came in and took videos of the robot working. They put the camera on top of the robot and ran it around the track in the room.

Project 14 PT How efficient is a hydraulic system

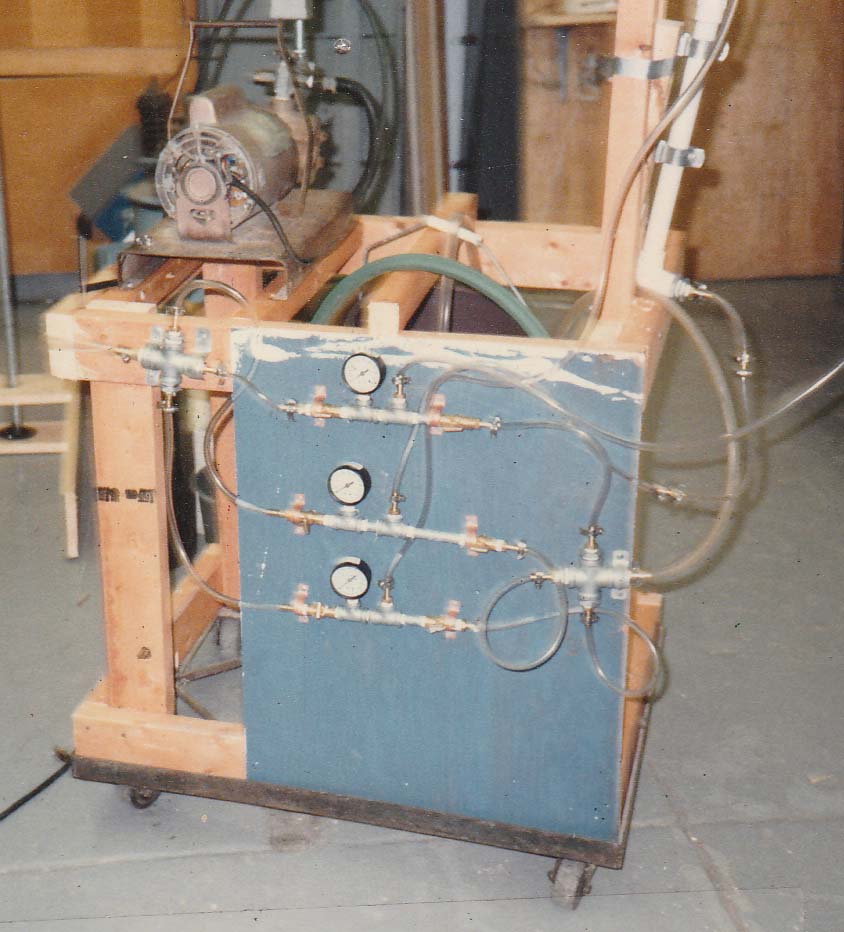

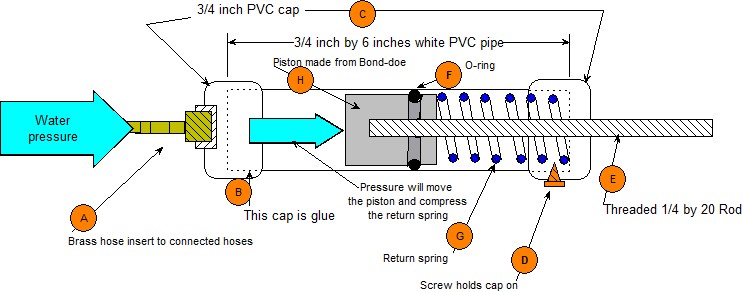

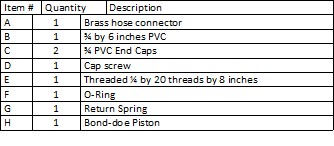

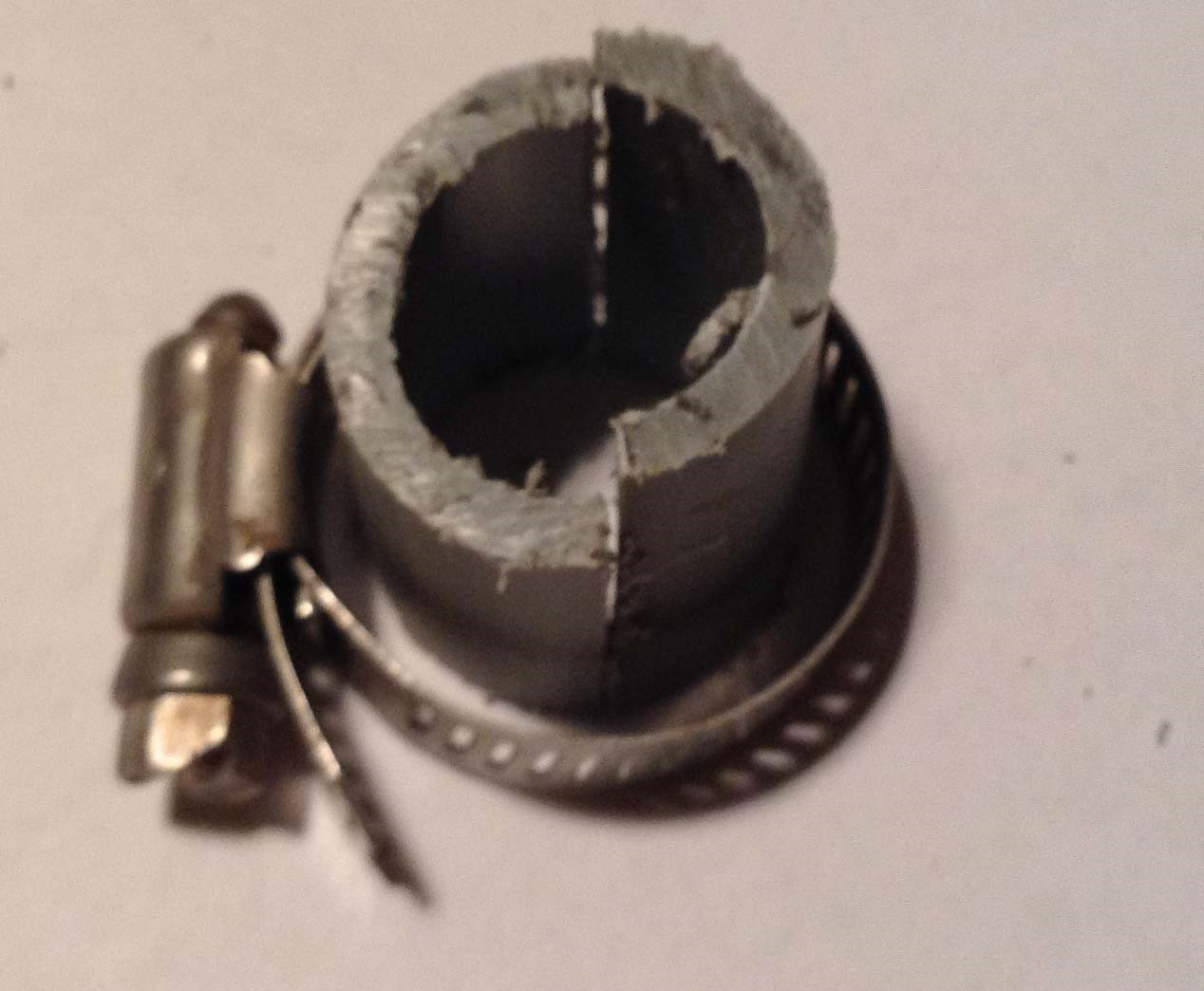

Picture above, left, shows hydraulic pistons we built from starch. Picture above, right shows pressor gages

The drawing above the parts table is how a homemade piston is made. The ¾ inch PVC caps on the water side is glued so the water will not leak and the old ring keeps the water from leaking around the piston. As you apply water pressure it moves the piston to the right and as you take pressure off, the return spring will push the piston back where it works like a regular hydraulic piston. .

The drawing above the parts table is how a homemade piston is made. The ¾ inch PVC caps on the water side is glued so the water will not leak and the old ring keeps the water from leaking around the piston. As you apply water pressure it moves the piston to the right and as you take pressure off, the return spring will push the piston back where it works like a regular hydraulic piston. .

The Picture below shows the hose insert that connects the water line, so you can see the water flow through the clear plastic.pipe.

The Picture to the Top left, shows a ¾ inch by 6 inches PVC pipe that is the main cylinder of the piston. There is also one of the end caps in the picture.

The Picture to the Top left, shows a ¾ inch by 6 inches PVC pipe that is the main cylinder of the piston. There is also one of the end caps in the picture.

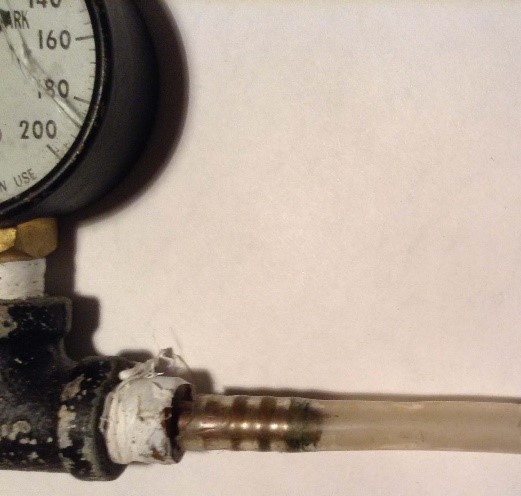

The Picture to top left and Bottom center, is how we made the piston mold. We cut a piece of pipe about an inch to two inches long, cut it in half, put a hose clamp around it to make a mold. Tighten it up and put duct tape on the bottom so that the bond-doe will not run out the bottom. Then we took a ¼ 20 threaded rod by 8 inches and stick it down into the mold before the bond doe start setting up. It usually takes about 10 minutes for the bond-doe to start to set up.

The Picture to top left and Bottom center, is how we made the piston mold. We cut a piece of pipe about an inch to two inches long, cut it in half, put a hose clamp around it to make a mold. Tighten it up and put duct tape on the bottom so that the bond-doe will not run out the bottom. Then we took a ¼ 20 threaded rod by 8 inches and stick it down into the mold before the bond doe start setting up. It usually takes about 10 minutes for the bond-doe to start to set up.

The picture above left show each piston has a gage on it. All the supply for this project 14 can be purchase at a local hardware store. Make sure the O-Ring is larger than the piston and it fit in the groove. At least half the O-Ring need to stick out pass the piston.

The picture above left show each piston has a gage on it. All the supply for this project 14 can be purchase at a local hardware store. Make sure the O-Ring is larger than the piston and it fit in the groove. At least half the O-Ring need to stick out pass the piston.

You need a razor blade and a tube of Super Glue. You cut the O-Ring and put it around in the groove and mark it to fit. Cut it and glue that together and it is perfect for this type of project and start rolling it over the top of the piston until it falls into the grooves. That will block the water from coming into the return spring chamber.

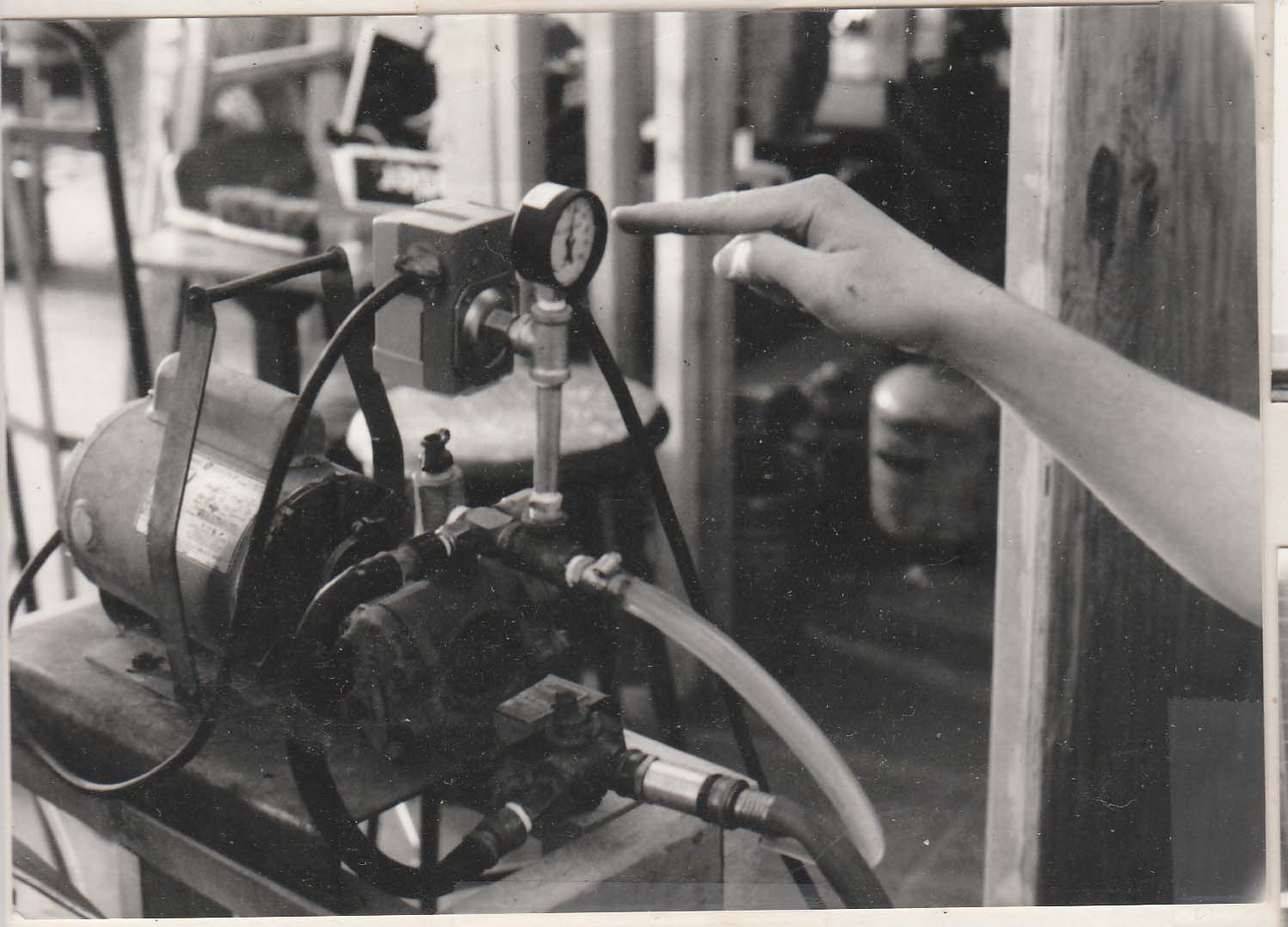

There is a water pump on top of the box, with a main pressure gauges to read the total pressure. Picture 20 there is a pressure gage on each pistons. We can calculate how much Work it takes to measure the efficient of the system. There is a pressure regulator to keep the pressure from getting to high.

There is a water pump on top of the box, with a main pressure gauges to read the total pressure. Picture 20 there is a pressure gage on each pistons. We can calculate how much Work it takes to measure the efficient of the system. There is a pressure regulator to keep the pressure from getting to high.

Project 15 PT How Efficient is a pulley symtem

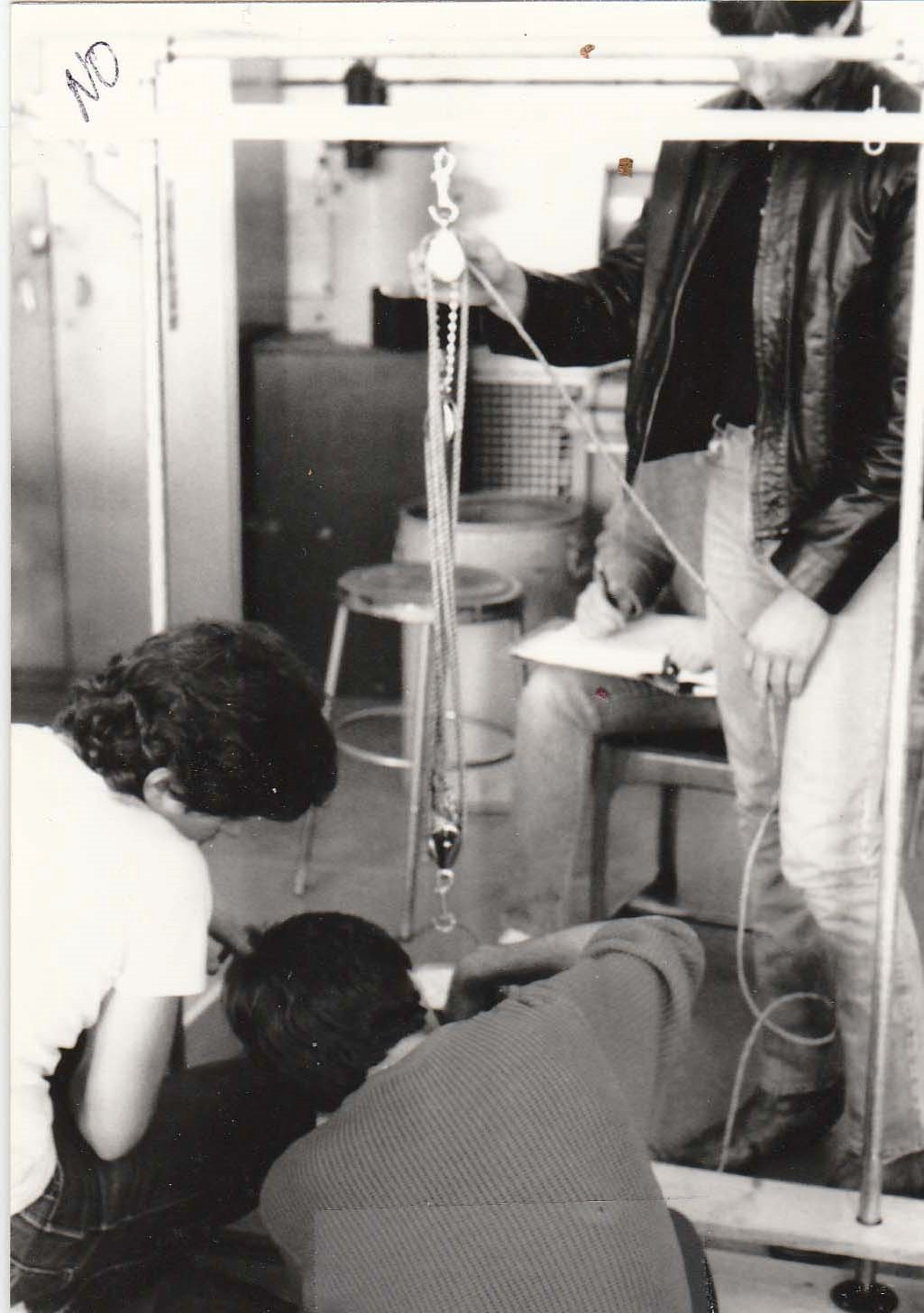

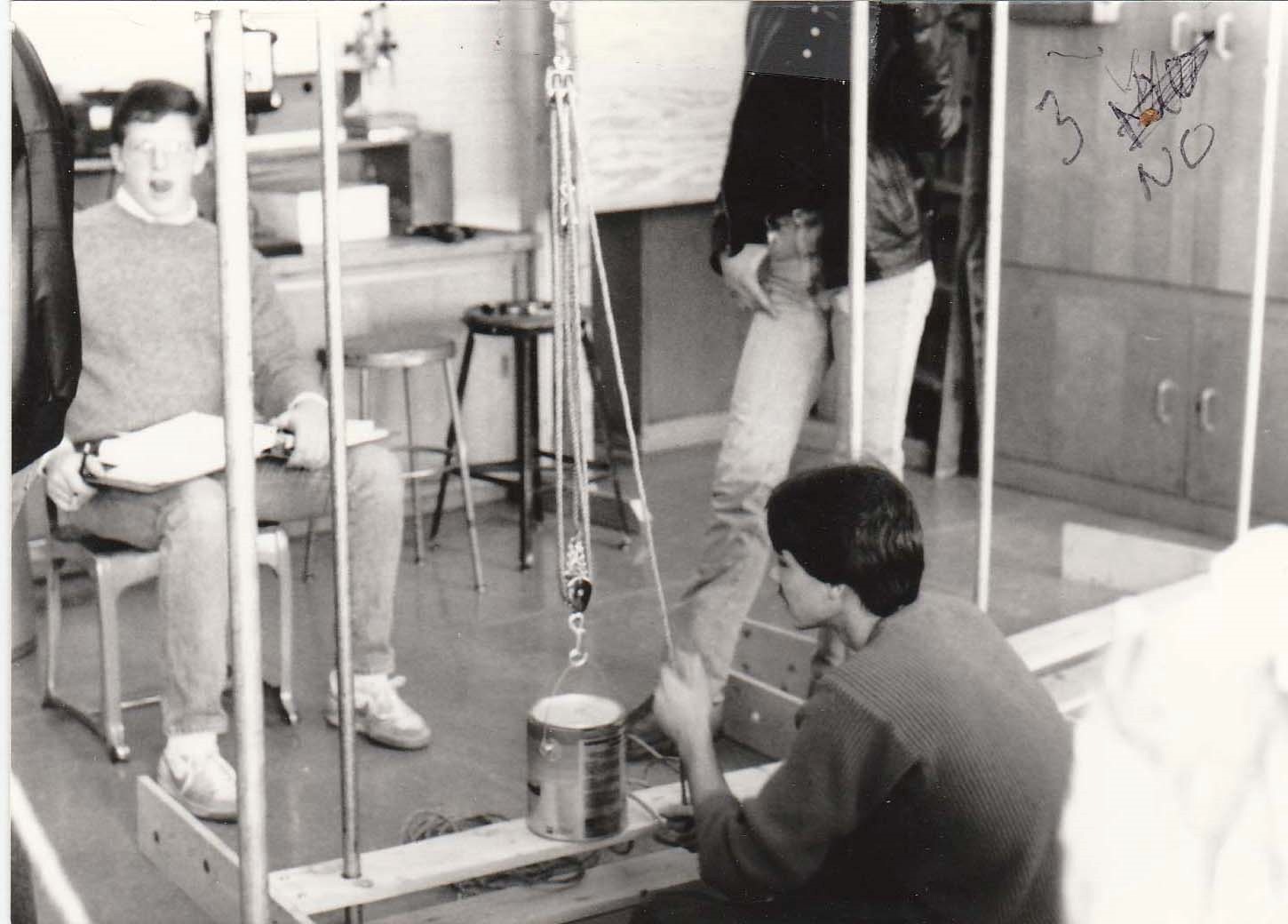

Picture top left and top center is where they are learning about pulleys. One pulley, two pulley, three pulley and four pulleys system to lift the load with ropes and pulleys.

Picture top left and top center is where they are learning about pulleys. One pulley, two pulley, three pulley and four pulleys system to lift the load with ropes and pulleys. The Picture top left, show the student learning how to use the pulley system. They calculate how much input work goes into the pulley system and how much work come out of the system. They lifting a load and looks like a four pulley system they strung up and made work.

The Picture top left, show the student learning how to use the pulley system. They calculate how much input work goes into the pulley system and how much work come out of the system. They lifting a load and looks like a four pulley system they strung up and made work.are lifting a paint can and seeing how much work it took to lift it a foot.

Project 16 Believe it or Not

Just a little background on the classroom, I had the students face away from the windows where they could not see what was going on outside.I was lecturing to my students, as I was standing at my desk, I saw a body go pass my classroom window. I heard the body hit the ground. I ran over to the window, opened it up and the student was getting up out of the mud. It had been drizzling rain all day. I asked him what he was doing. He said he was practicing his mountain climbing so I told him he needed to go get cleaned up and go to the office and tell the principal what you had done. He said I just wanted to get out of the math teacher’s classroom early so I could run to Swain’s to get something to eat. He said it was close to bell time anyway so that was the story and a couple of days later, the math teacher came down to my class where I was working and chewed me out from one end to the other about no body skipped her math class by jumping out the window. I did not say anything. I just let her blow her steam off. She left and my class was all opened-eyed and I said “Boy that is what you call a real ass-shewing”. Of course, they all laughed but I do not know what ever happened with him but that is one of the strange stories that happened while I was in teaching profession.

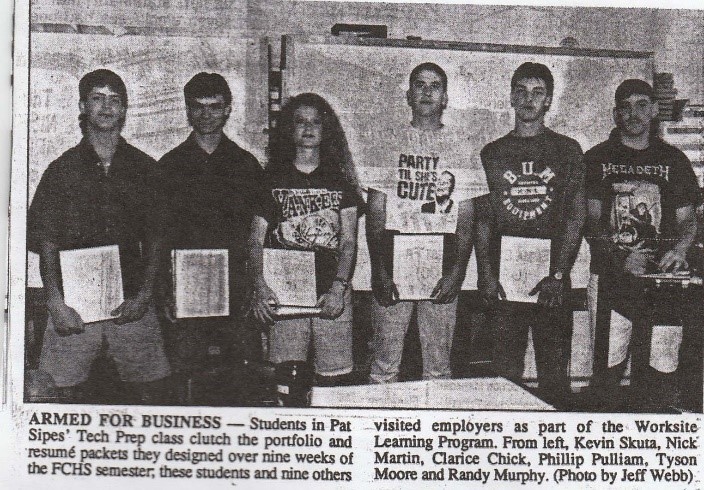

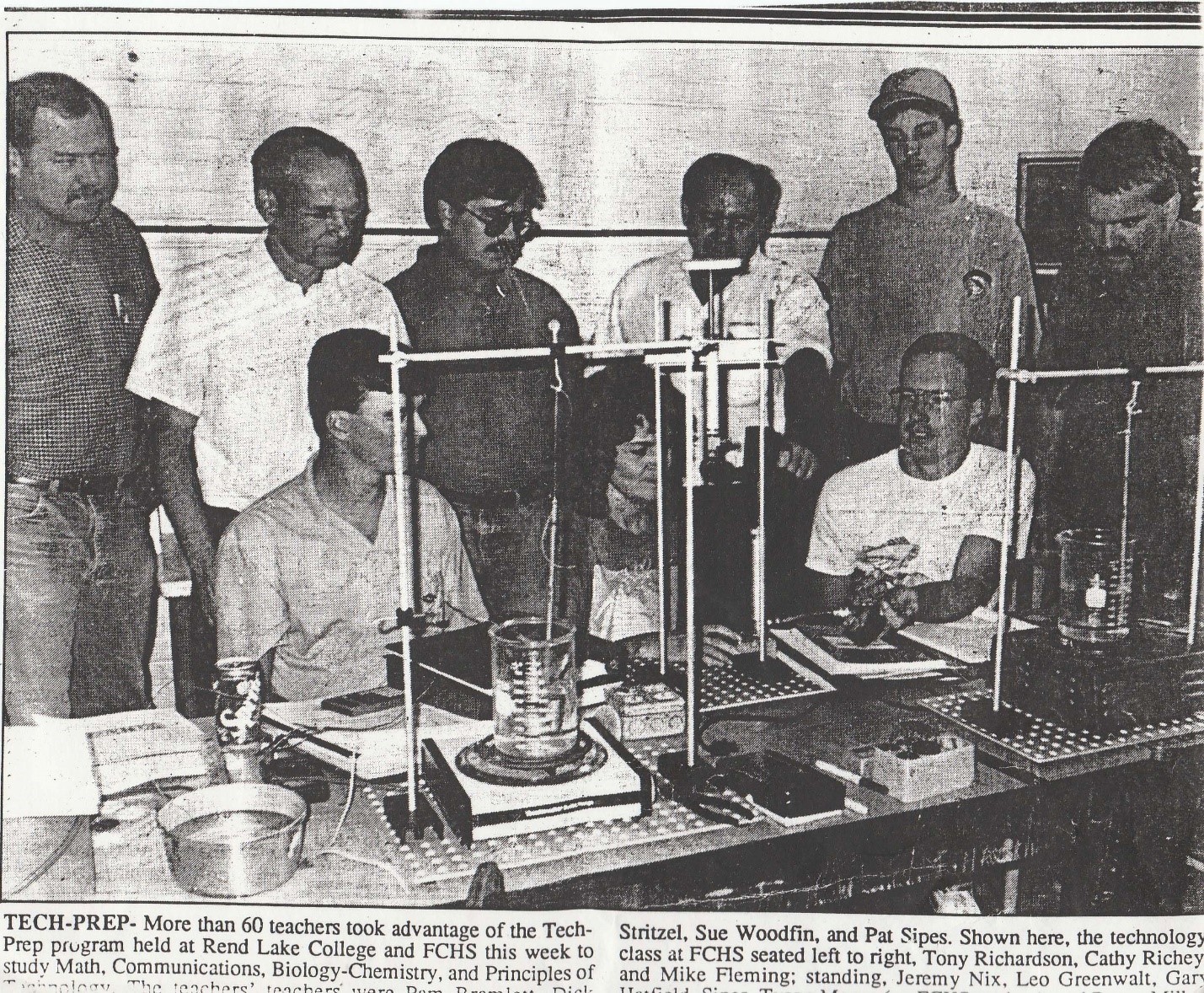

Project 17 ….Betty Musgraves & Tech Prep

The picture top left, is of the tech prep teachers in Franklin county. They get together several times a year and go over the new books and equipment that comes into the PT program. The lady in the front row is Betty Musgrave. She contributed a lot of time and money to the PT program by writing grants and getting other schools involved. We had a tremendous PT and electronic programs. I would not have had half the things that I got if it was not for Betty Musgrave.

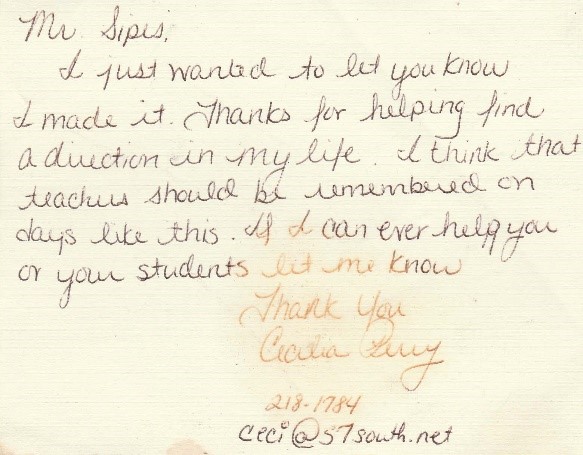

The picture top left, is of the tech prep teachers in Franklin county. They get together several times a year and go over the new books and equipment that comes into the PT program. The lady in the front row is Betty Musgrave. She contributed a lot of time and money to the PT program by writing grants and getting other schools involved. We had a tremendous PT and electronic programs. I would not have had half the things that I got if it was not for Betty Musgrave.Project 18 Letters of Appreciation

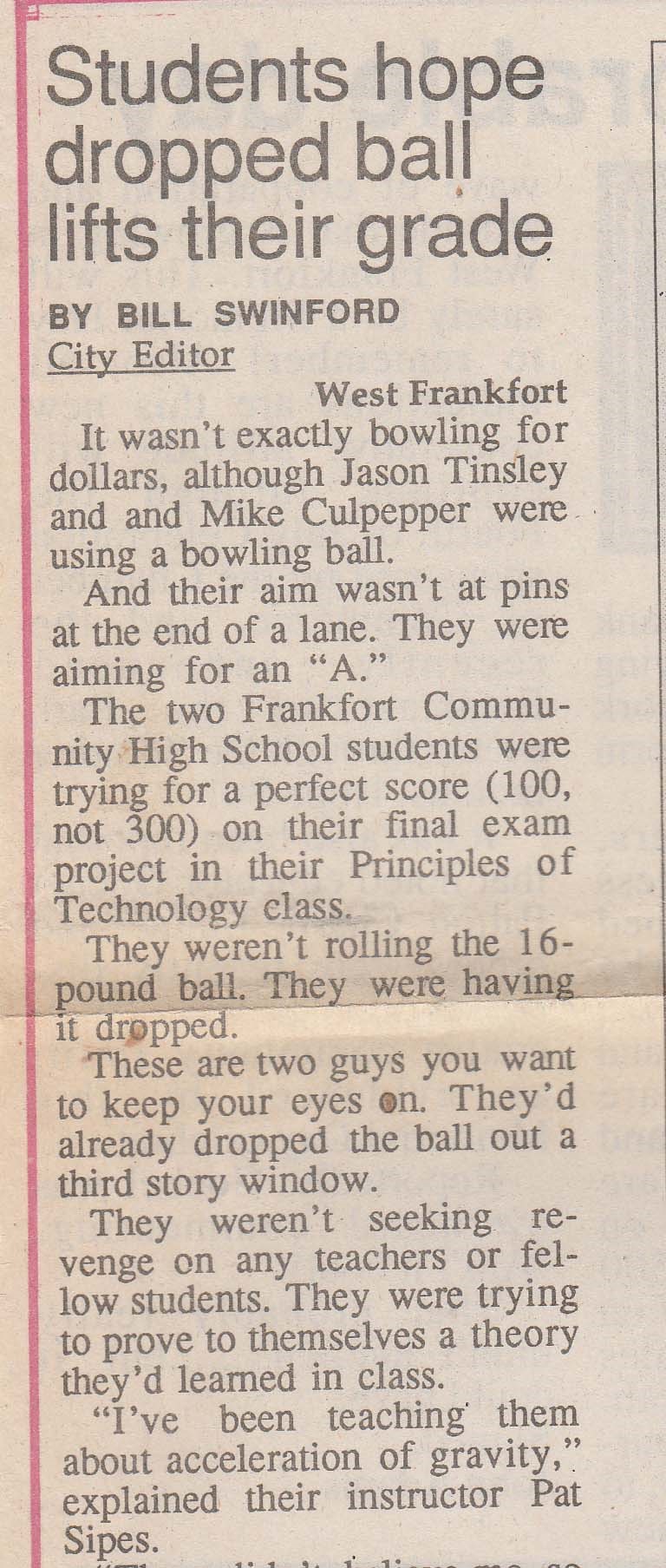

project 19 Principles of Technology

Picture above, is a picture of all the students that were in Principles of Technology. That was a little different than Tech Prep. The Principles of Technology is a new program that we started and of course we mixed it in with the Tech Prep. The students after completing the course could get a college credit at John A. and it was Tech Prep 1 and Tech Prep 2, Principles of Technology 1 and Principles of Technology 2.

Picture above, is a picture of all the students that were in Principles of Technology. That was a little different than Tech Prep. The Principles of Technology is a new program that we started and of course we mixed it in with the Tech Prep. The students after completing the course could get a college credit at John A. and it was Tech Prep 1 and Tech Prep 2, Principles of Technology 1 and Principles of Technology 2.

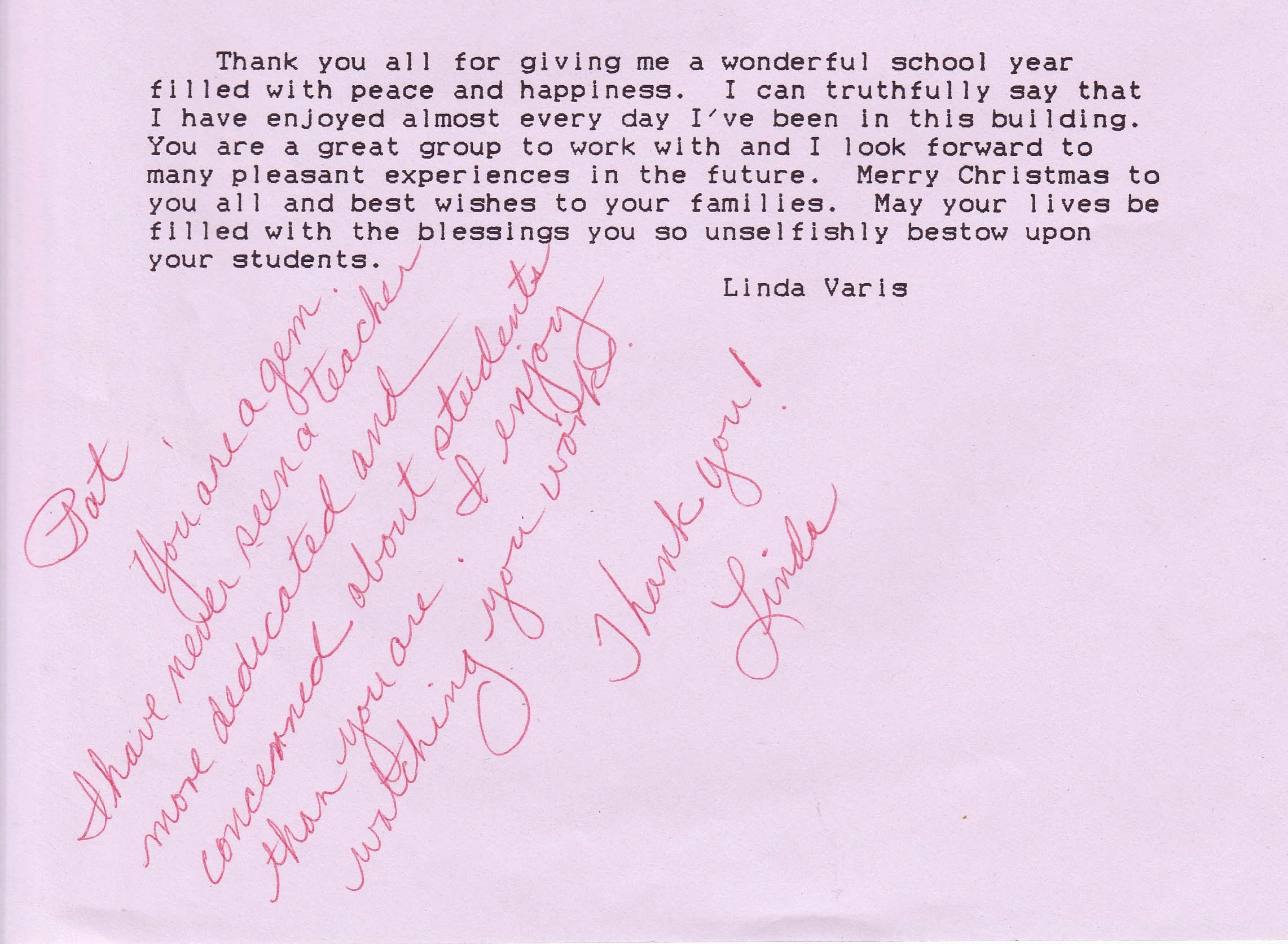

Project 20 Tech Prep @ Illinois State Capital

Picture above left, is when I took a group of students to the Capital building in Springfield, Illinois and we got to meet State Senator Mr. Ray and he looked at all of the projects that we had brought up to the fair and he was pretty impressed about it.

Picture above left, is when I took a group of students to the Capital building in Springfield, Illinois and we got to meet State Senator Mr. Ray and he looked at all of the projects that we had brought up to the fair and he was pretty impressed about it.

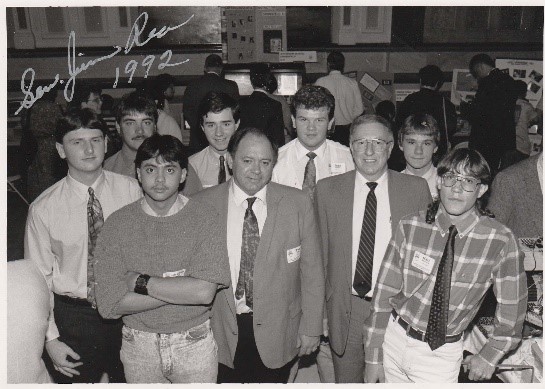

project 21 Chief invited to US Army post, Fort Benning

The Picture top-left, is me doing some paper work.

The Picture top-left, is me doing some paper work.

I was invited to the US Army Post in Fort Benning, Georgia and Alabama, because I had 9 students sign up for the army that school year. It was a weeklong trip and we stay on the army base. We got to see helicopters, trucks, airplane and Hum V. We went to the firing range, and spent the day. This was very exciting. We observe solider thronging grenade. This was exciting to.

Then we went to watch solider jump out of airplanes and that was at a fort near Fort Benning. That was exiting and they would fly at 1000 feet and then the solider would jump out and screaming and yell on their way down. It looked like to me that all the parachutes opened so I was happy with that

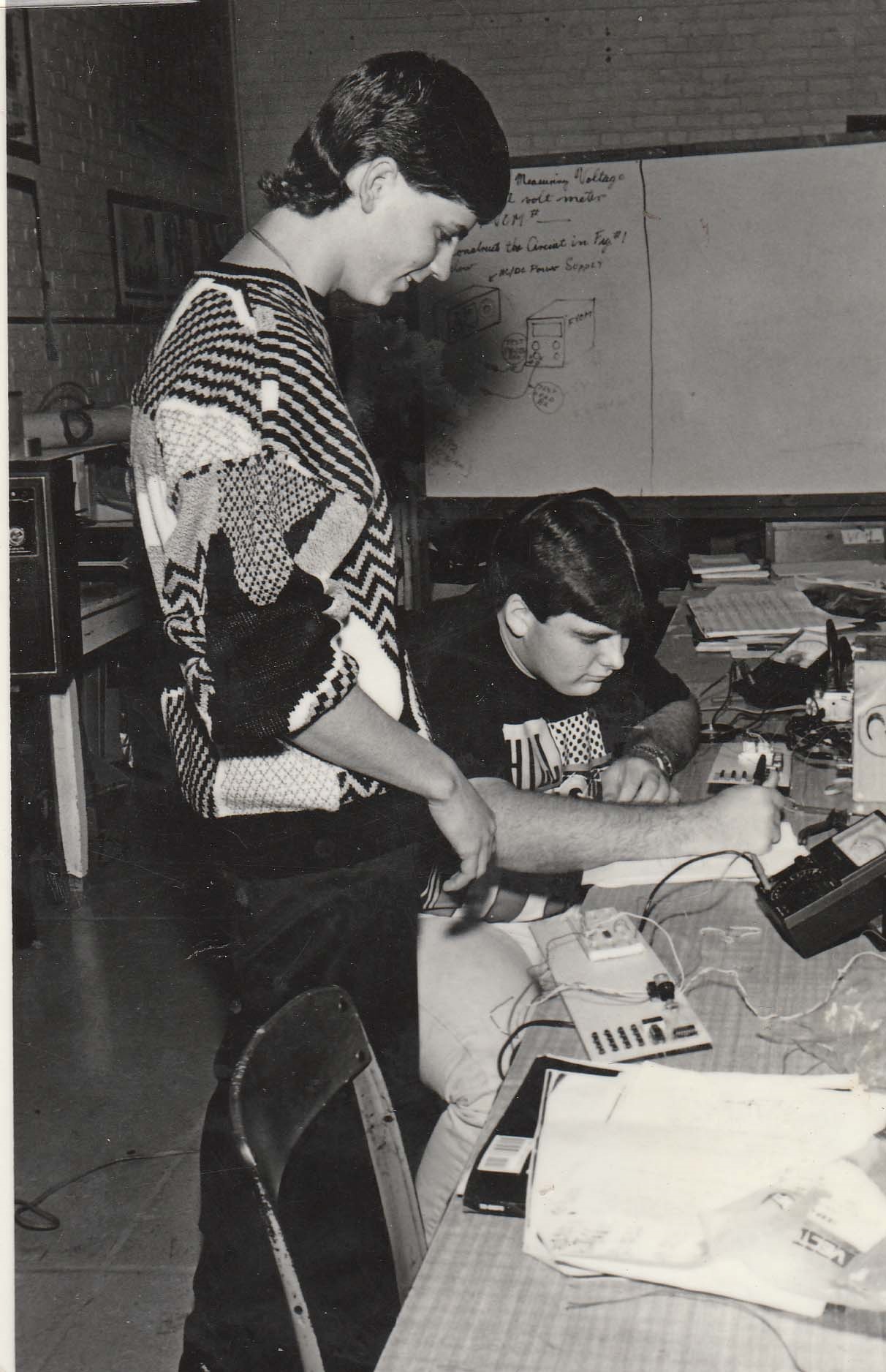

Project 22 Alex Burk and input/output interfaces

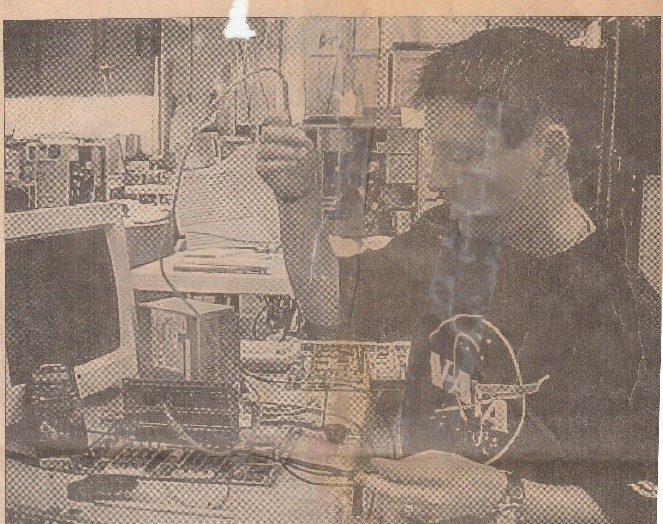

Picture above-left is Alex Burke. He is working on how to interface computers to the real world. He came up with a lot of good ideas after I showed him the basics. He built an interface for the input ports and I showed him how to build the interfaces for the output ports and how you can control robots and different pieces of equipment by hooking up to a lap top or desk top computer.

Picture above-left is Alex Burke. He is working on how to interface computers to the real world. He came up with a lot of good ideas after I showed him the basics. He built an interface for the input ports and I showed him how to build the interfaces for the output ports and how you can control robots and different pieces of equipment by hooking up to a lap top or desk top computer.

Project 23 So this is High School

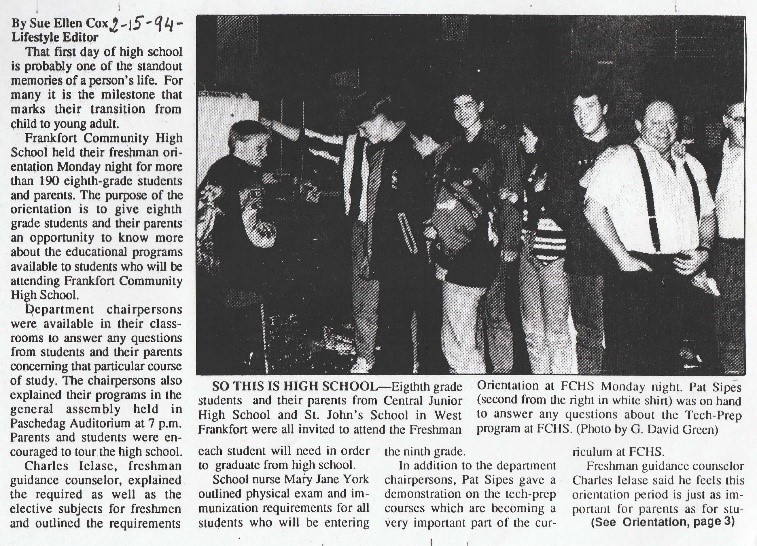

The Picture top-left, is where I used my students to recruit freshman coming in each year so they would have an orientation meeting with the parents and the students and they would come to my room and they would have all their projects set up for the students to show off their work of what they had done last year. This is usually done a couple of weeks before school starts.

The Picture top-left, is where I used my students to recruit freshman coming in each year so they would have an orientation meeting with the parents and the students and they would come to my room and they would have all their projects set up for the students to show off their work of what they had done last year. This is usually done a couple of weeks before school starts.Project 24 Ron Smelcer; Eaning College Credit

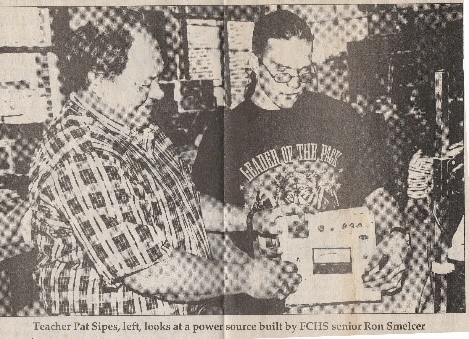

Picture top-left, is Ron Smellcer, is working on trying to graduate from John A in one year by taking night classes. I do not remember what the final outcome was but he was a hard working student.

Picture top-left, is Ron Smellcer, is working on trying to graduate from John A in one year by taking night classes. I do not remember what the final outcome was but he was a hard working student.

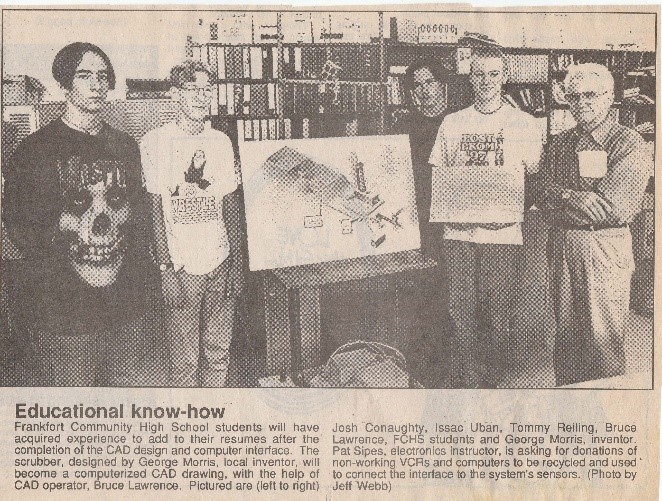

Project 25 Issac Uban and Design for coal Scrubber

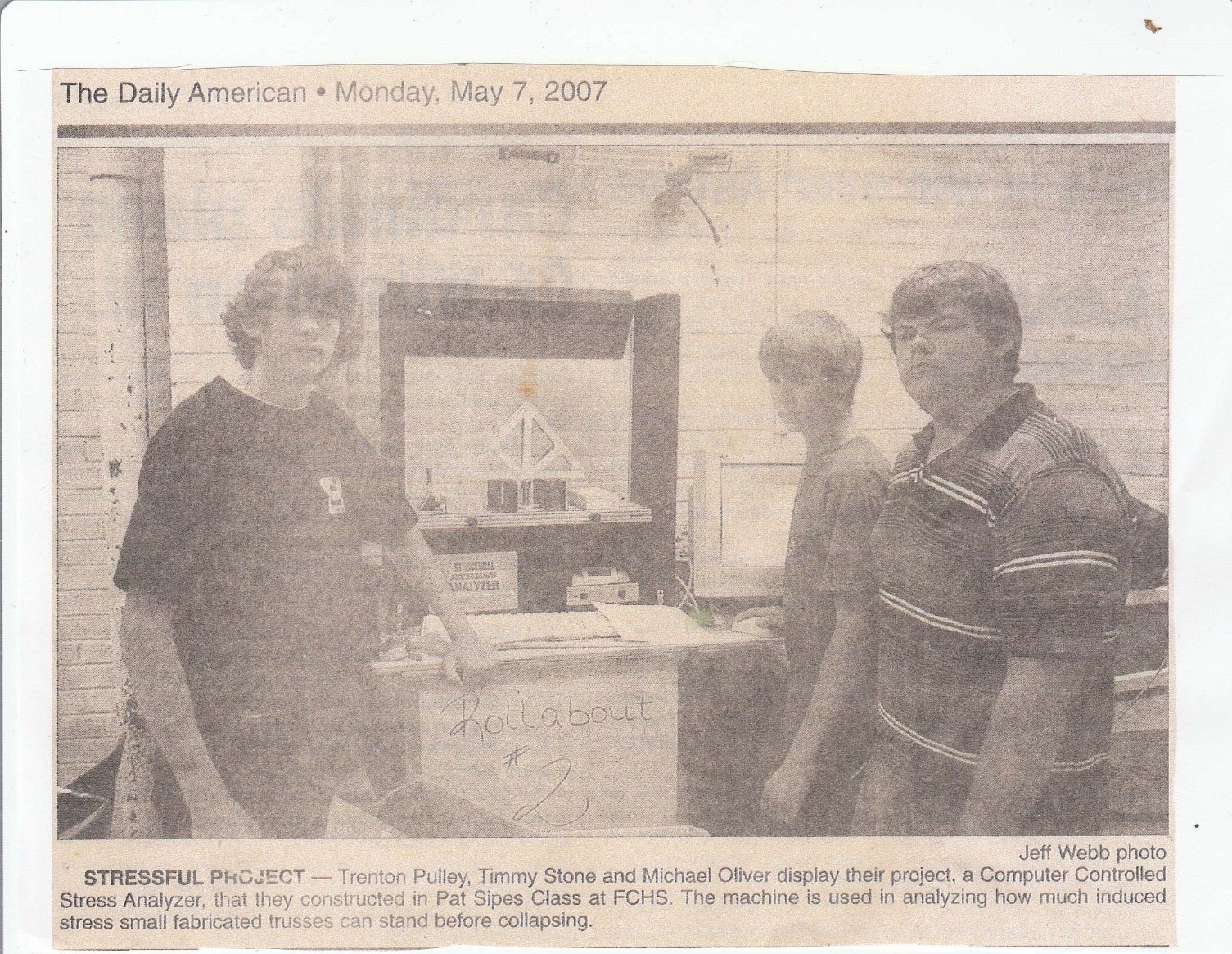

Project 26 Michael Olever & Stress Analyzer

Project 27 Mark Trone & STAR BURST

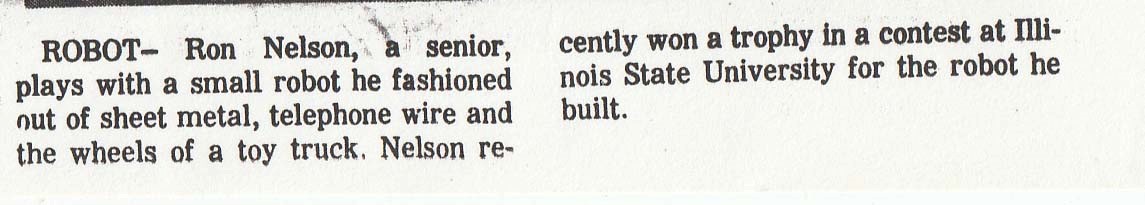

Project 28 Ron Nelson & First Tech Prep ROBOT

Project 29 Alex Burk & BOT

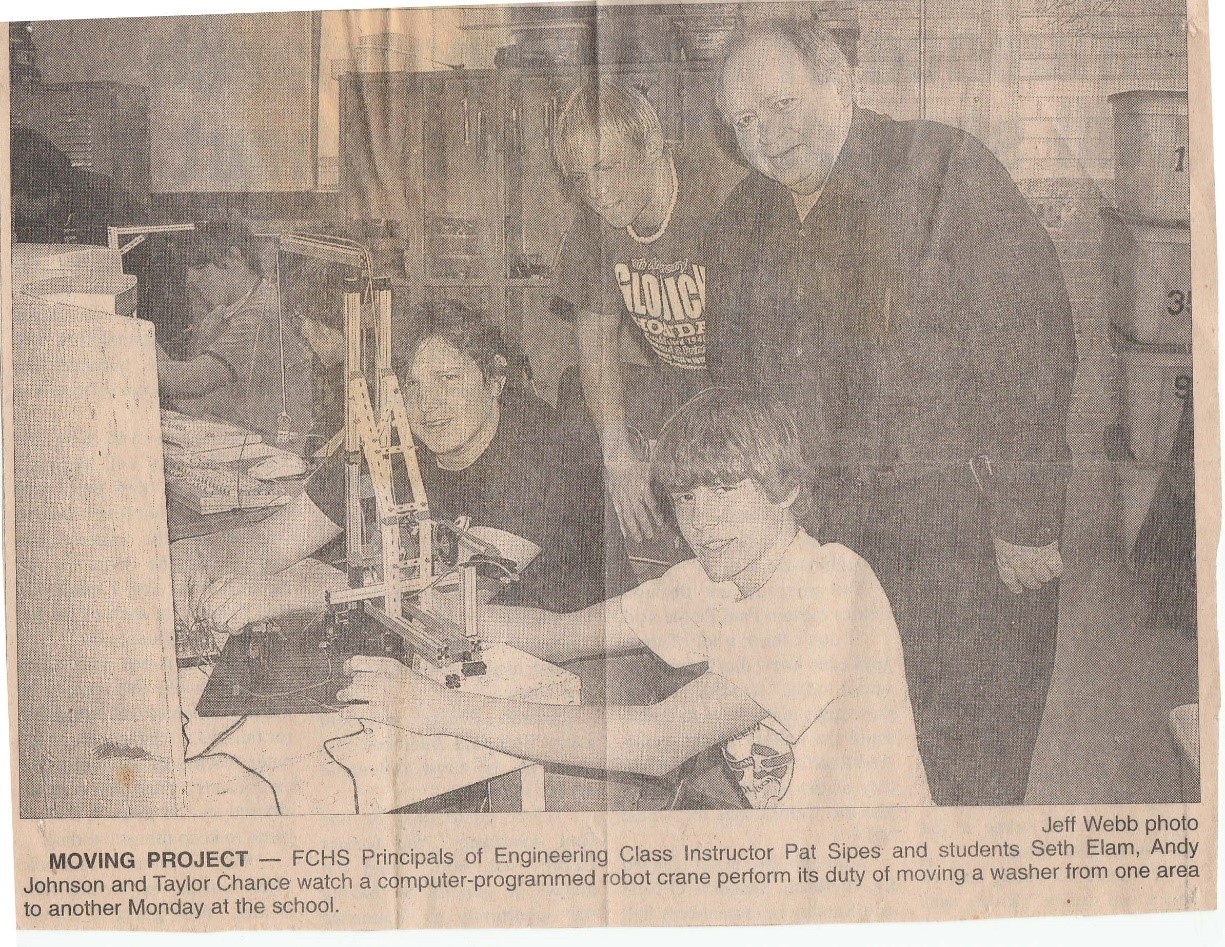

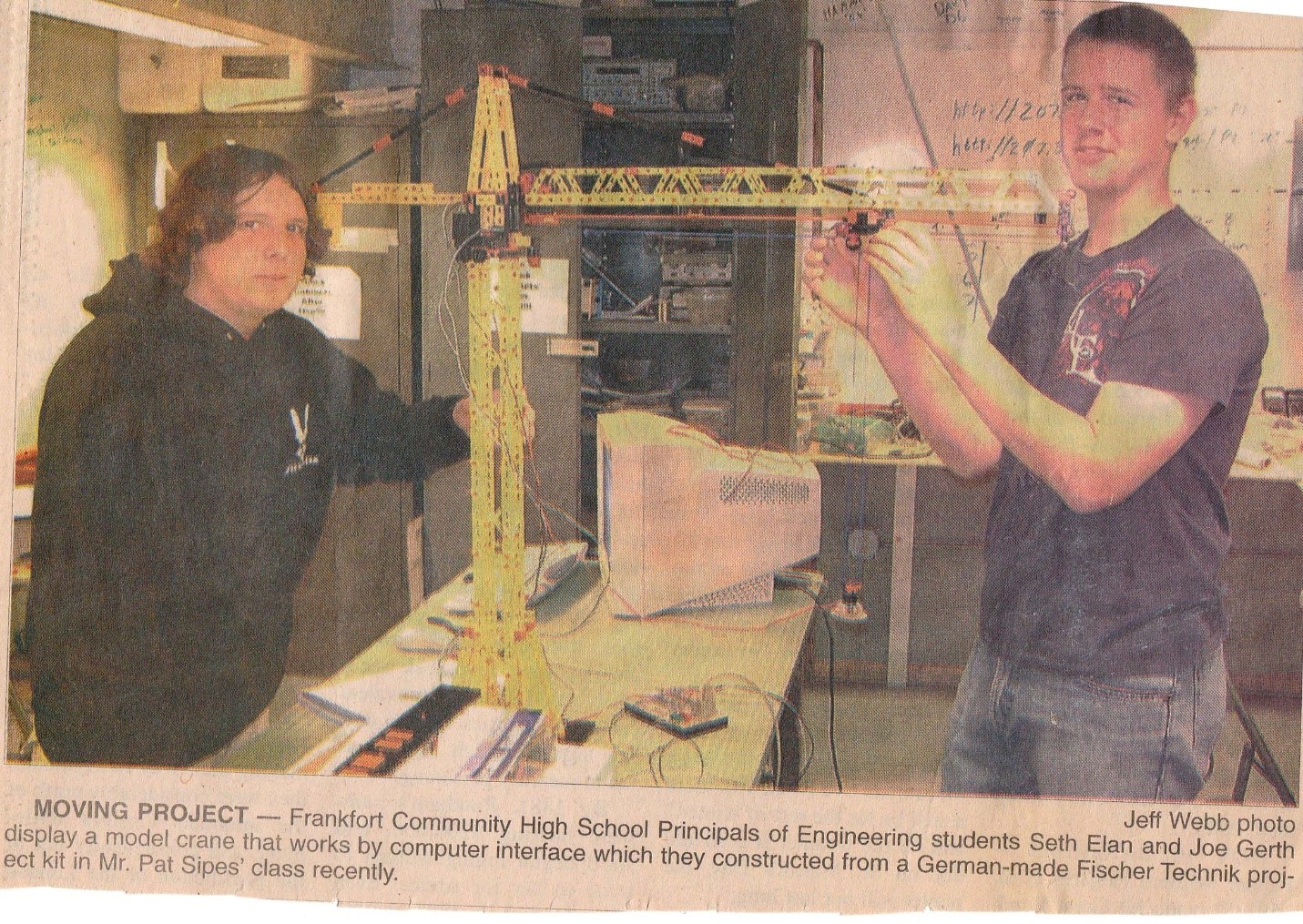

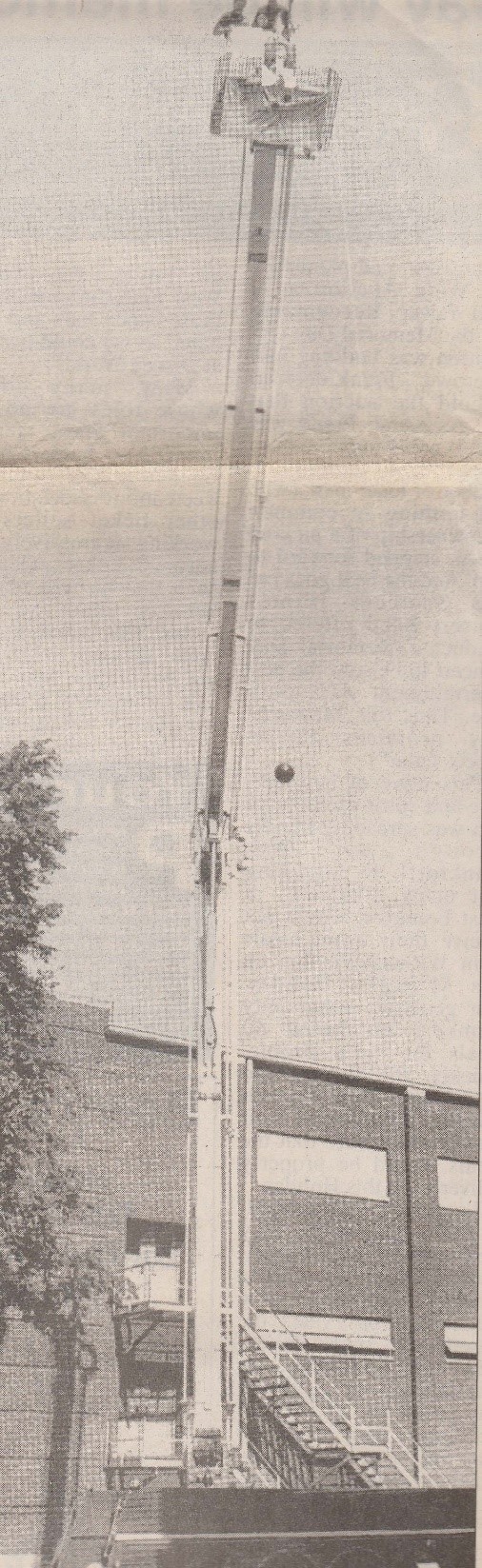

Project 30 Seth Elan & Small Crane

Project 31.0 Jason Moore & Candy Cane Lane

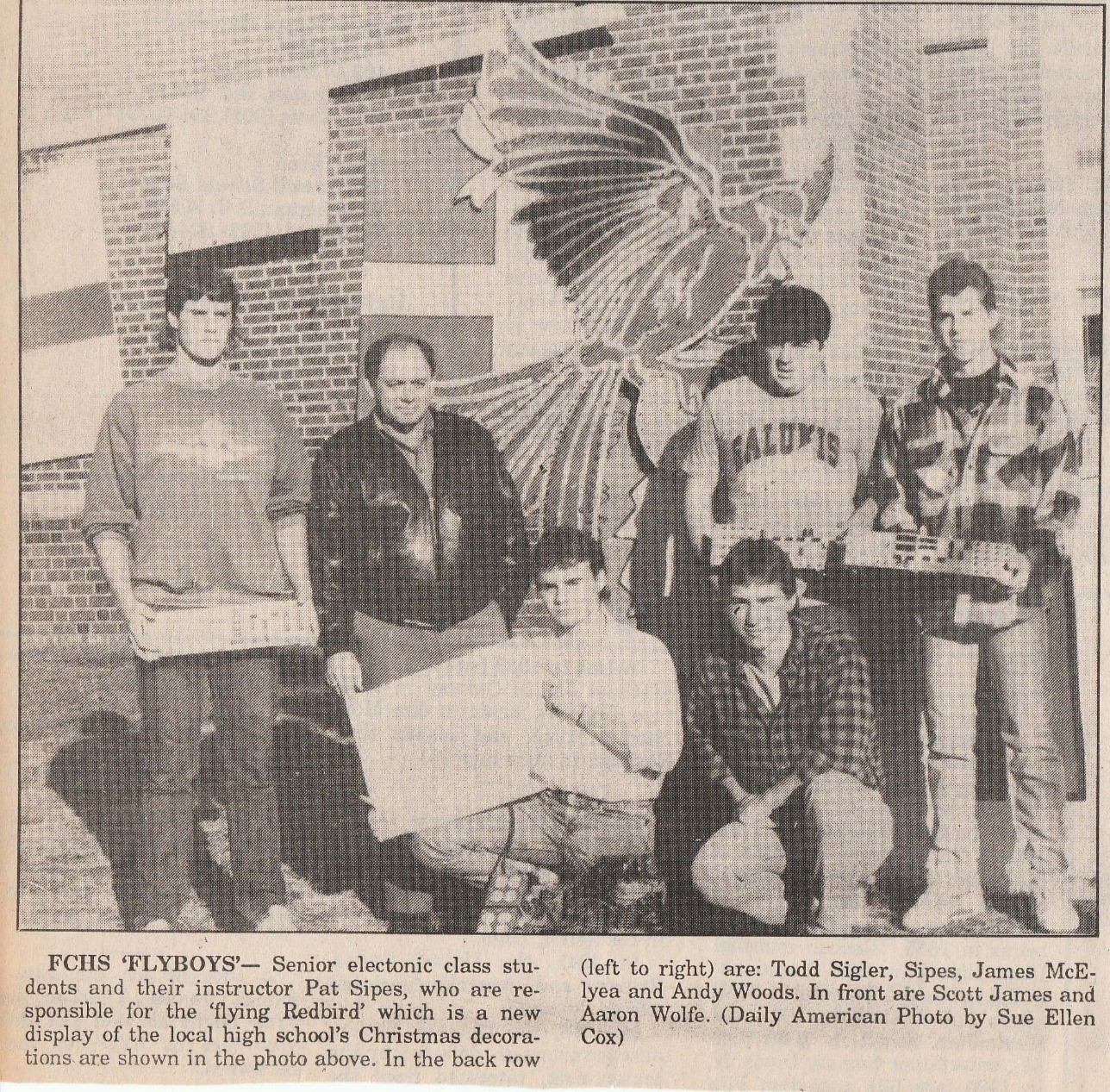

Project 32 Shane James & Flying Redbird

Project 33 Tyson Moore & Tech Prep

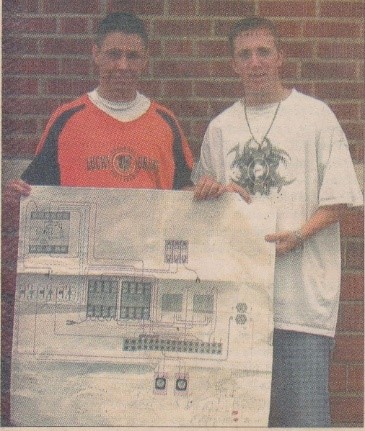

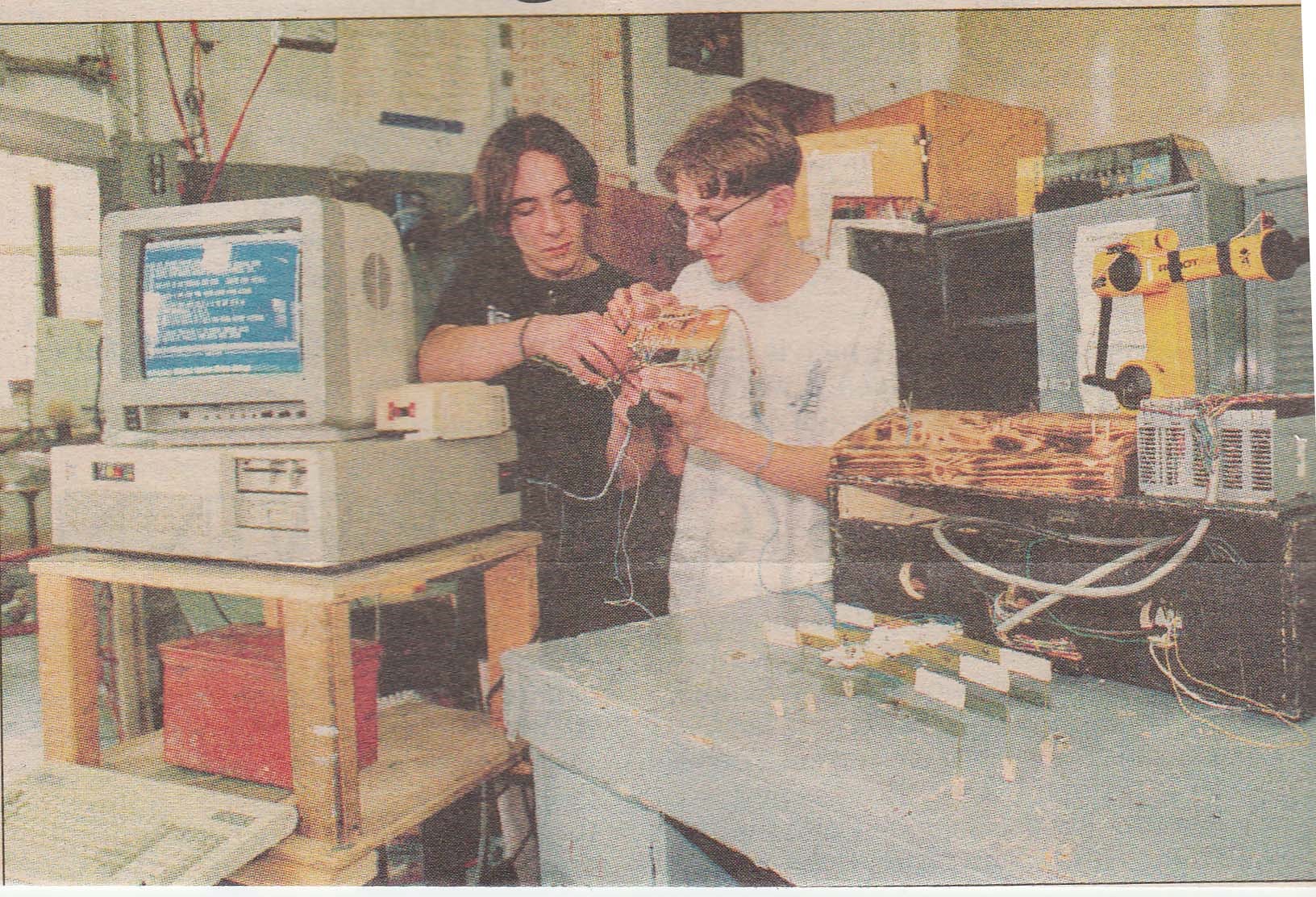

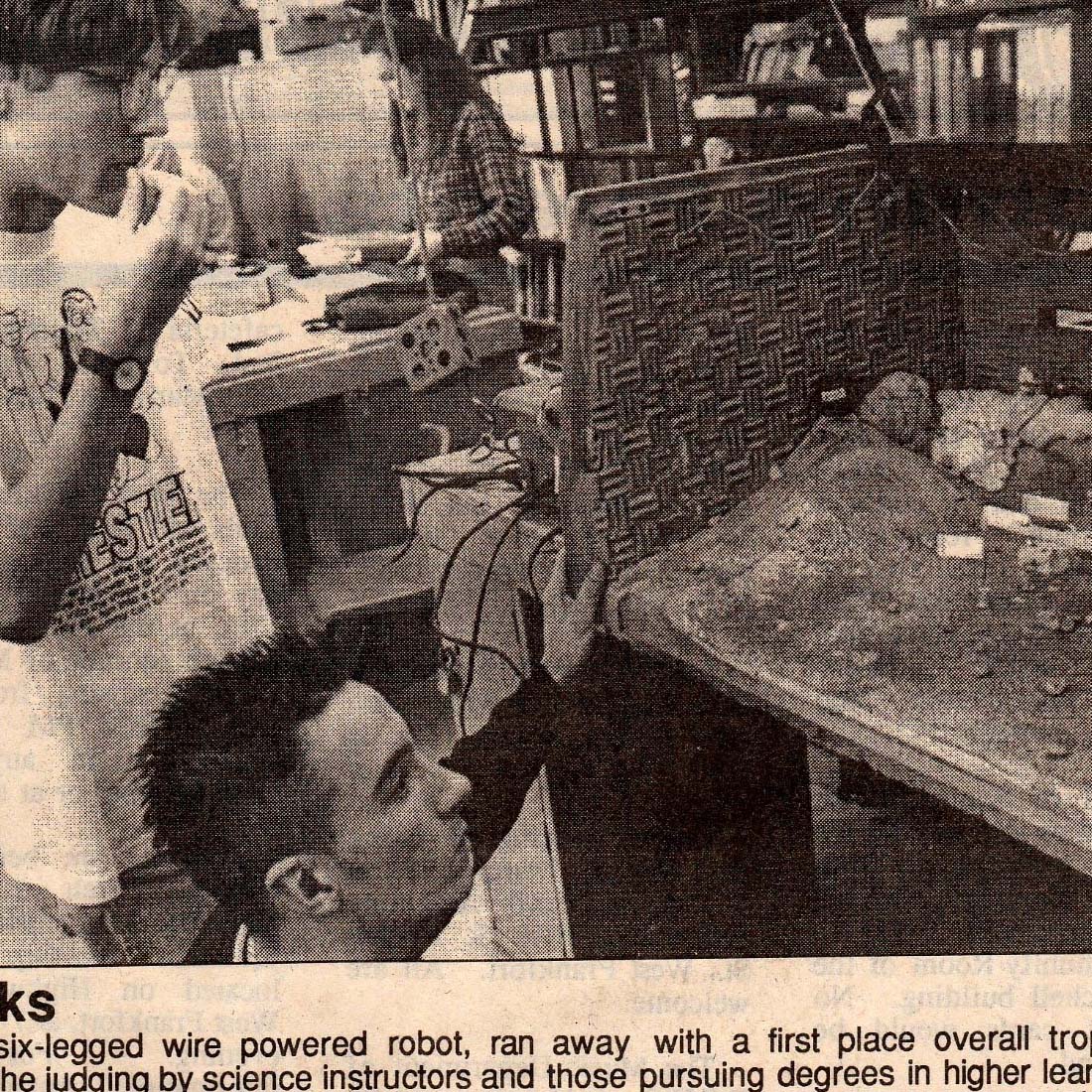

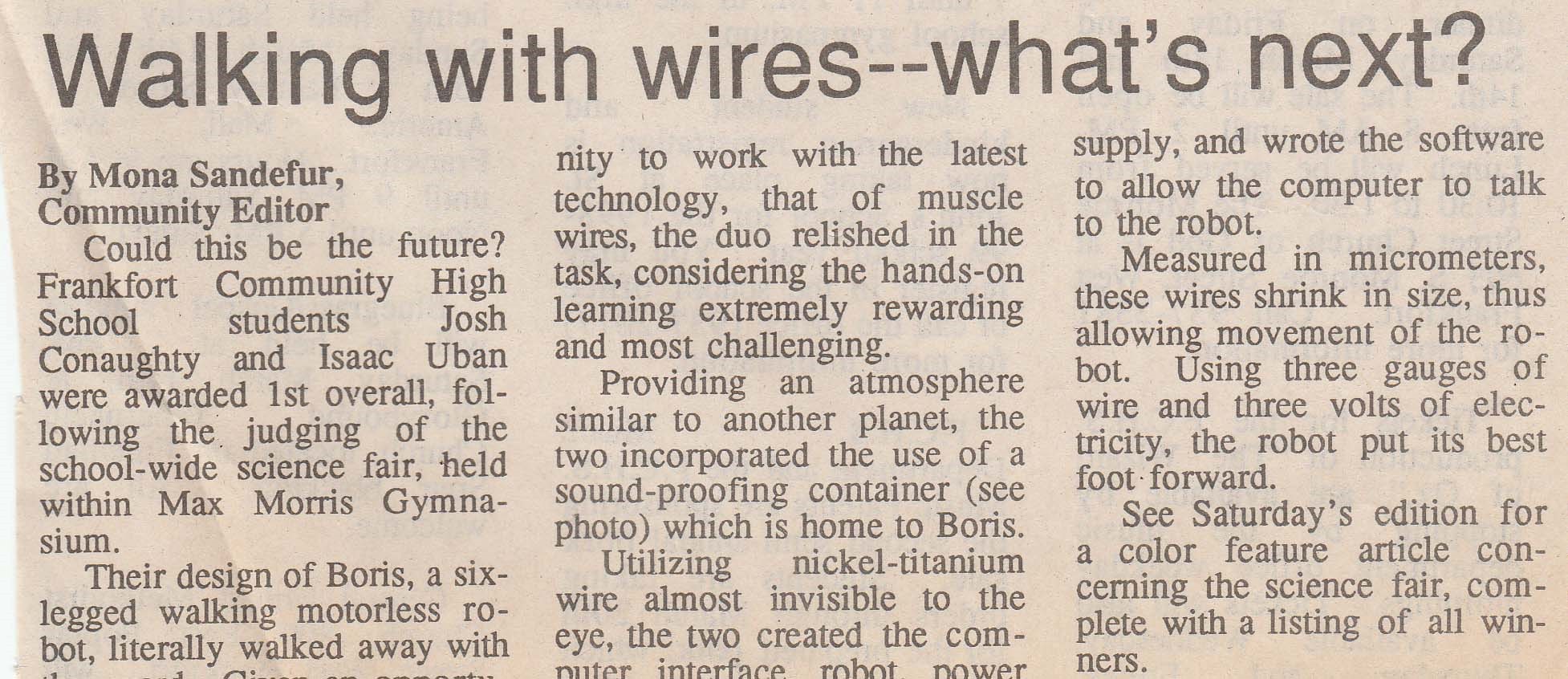

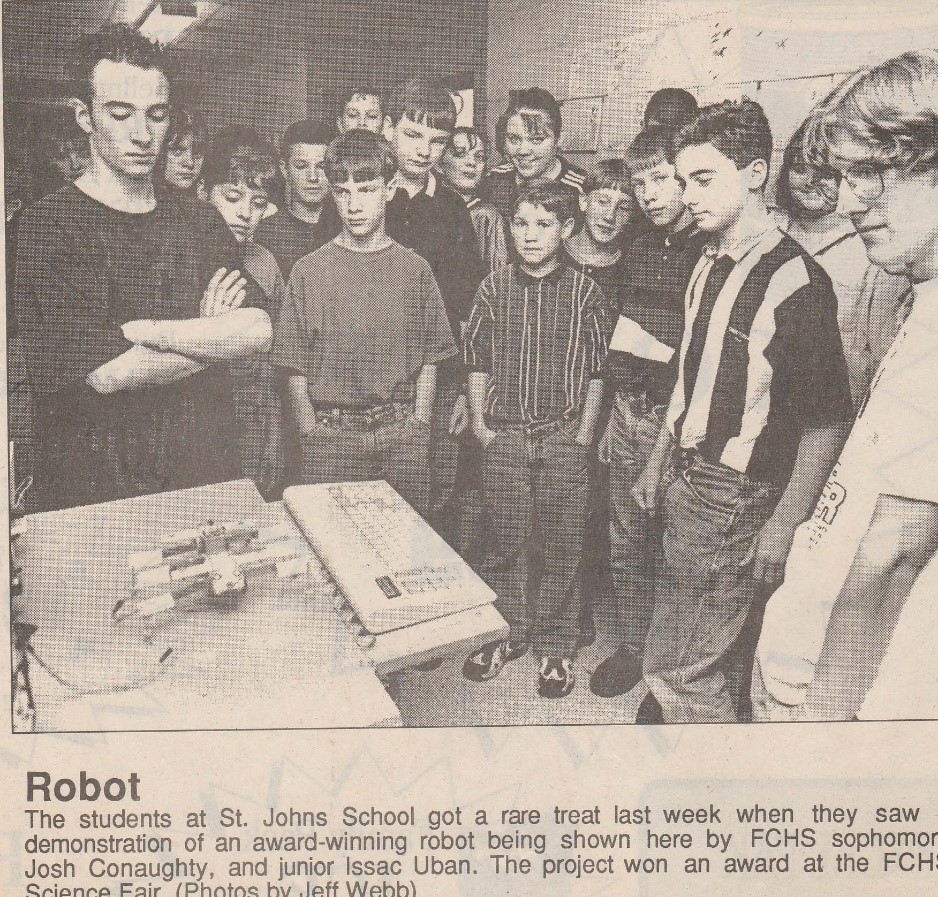

Project 34 Conughty/Uban & Providing the spark

Project 35 8085 home made computer

Project 35 8085 home made computer

Project 36 FCHS @ Springfield State Capital

![]()

Project 37 Dennis Ledbetter Experiment

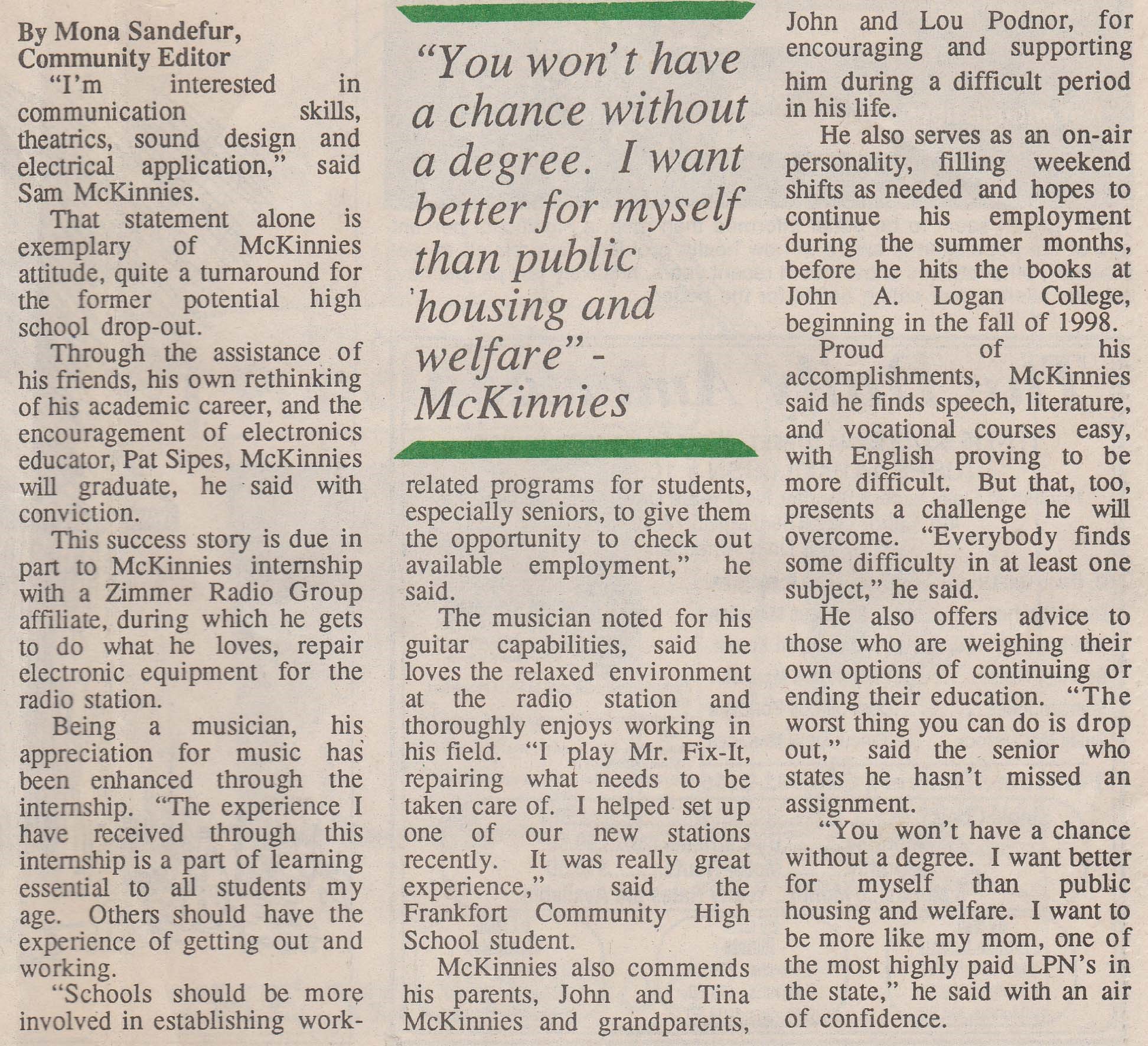

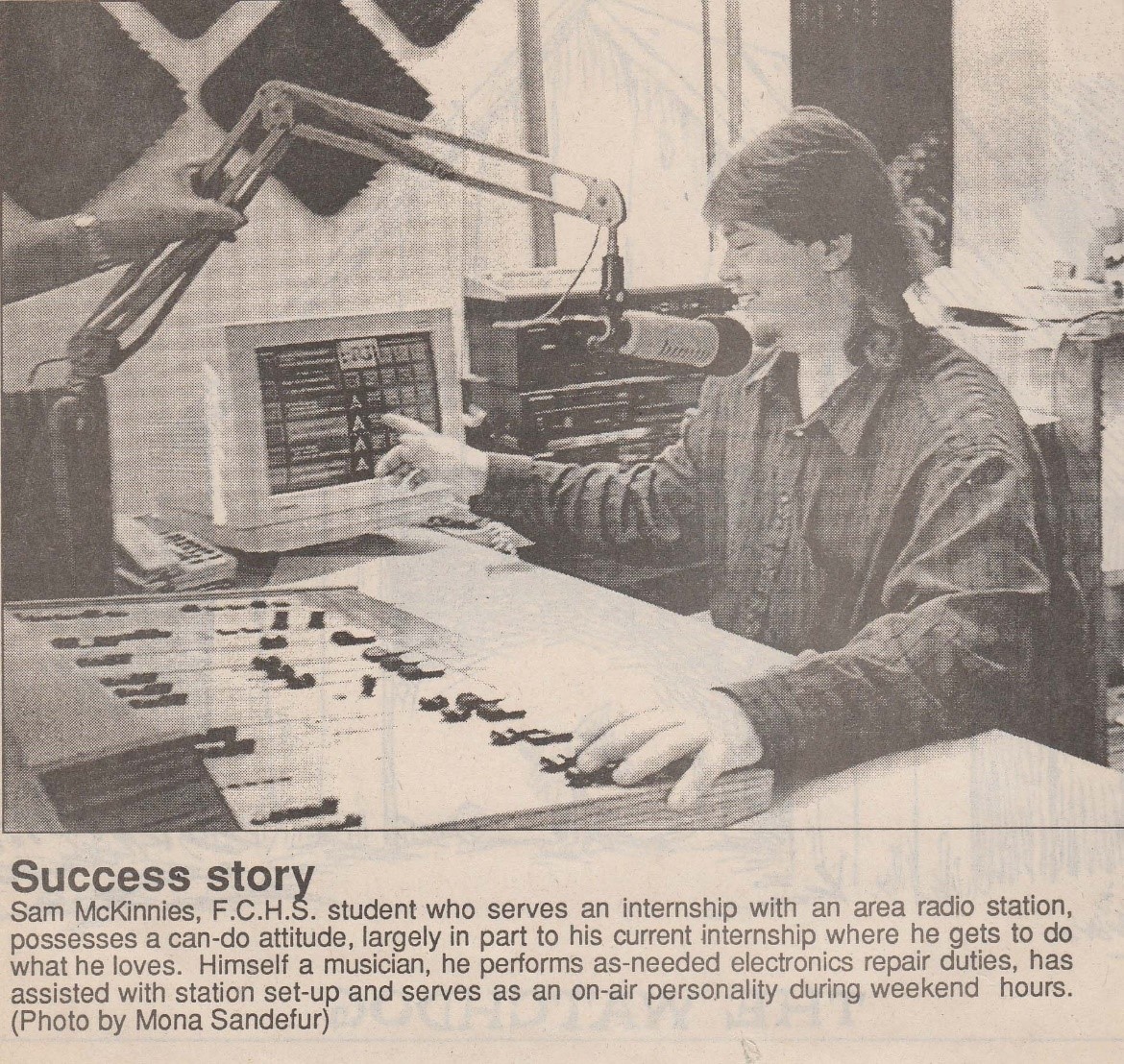

Project 38 Sam McKinnies Intership

![]()

![]()

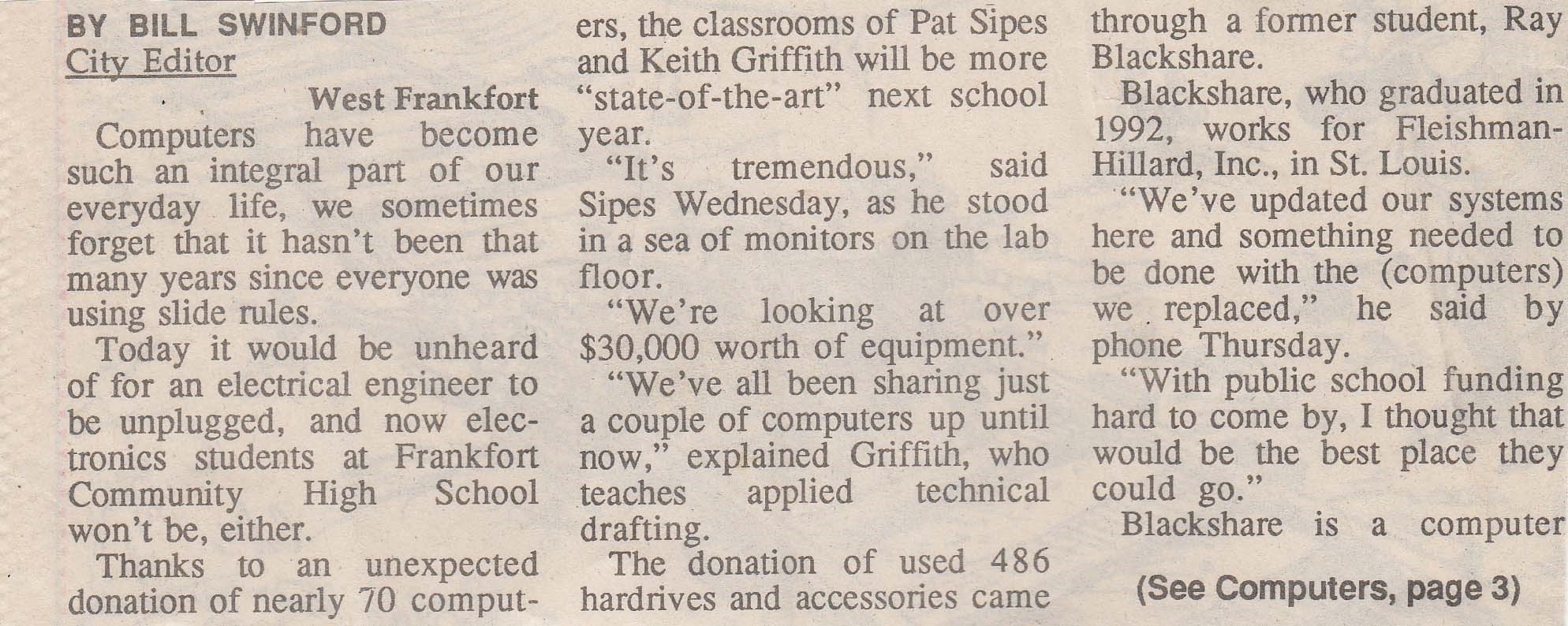

Project 39 Keith Griffith & Donation Computer

Project 40 Donation Meter

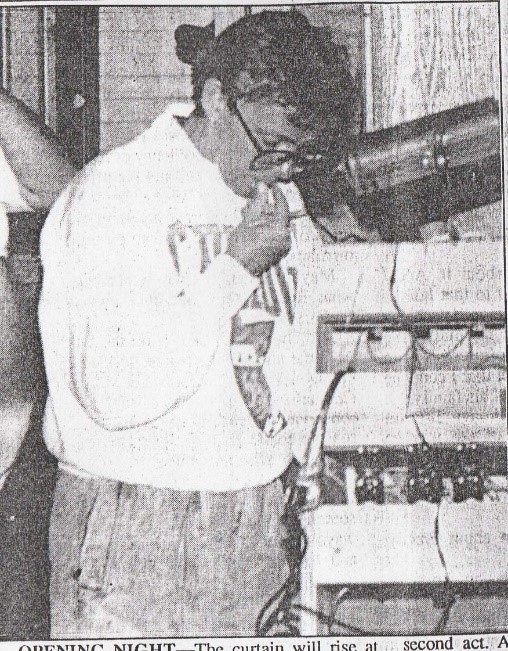

Project 41 Elecronic Class & The Phantom

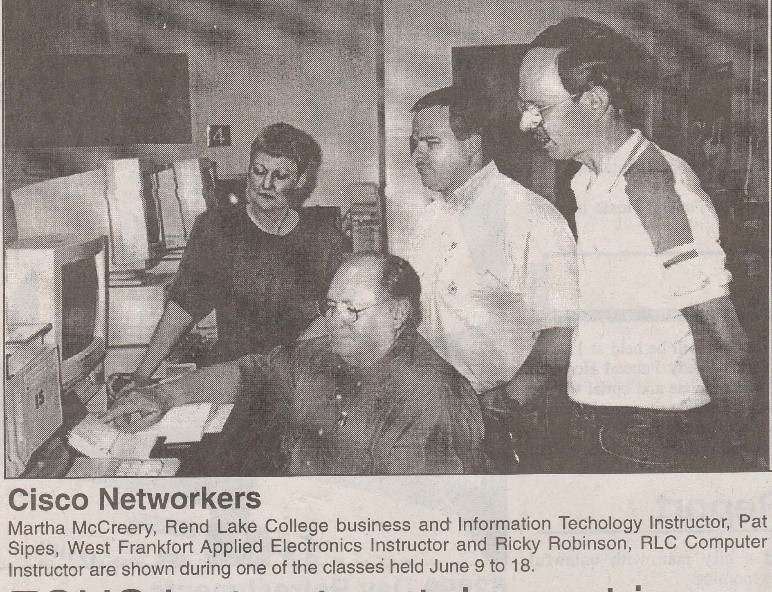

Project 42 Electronnic Class & CISCO

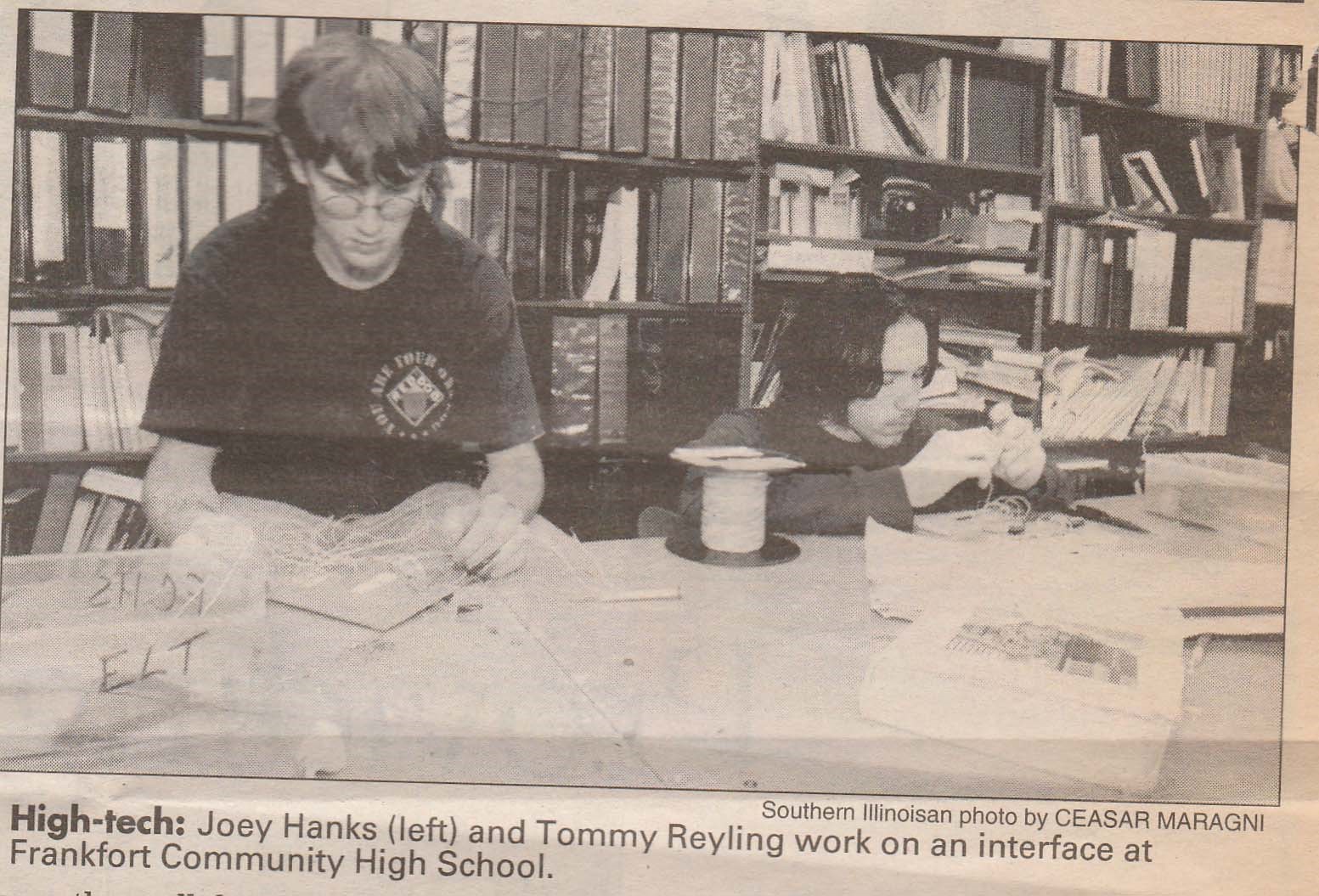

Project 43 Hanks & Reyling working on interface

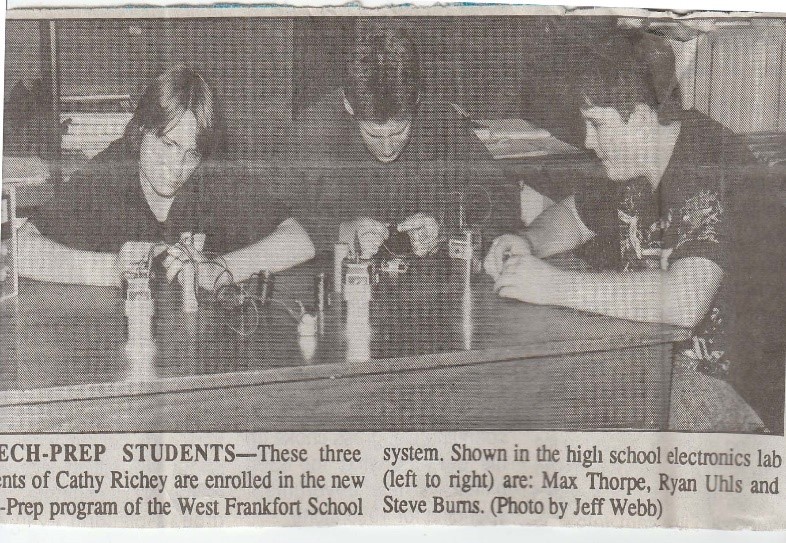

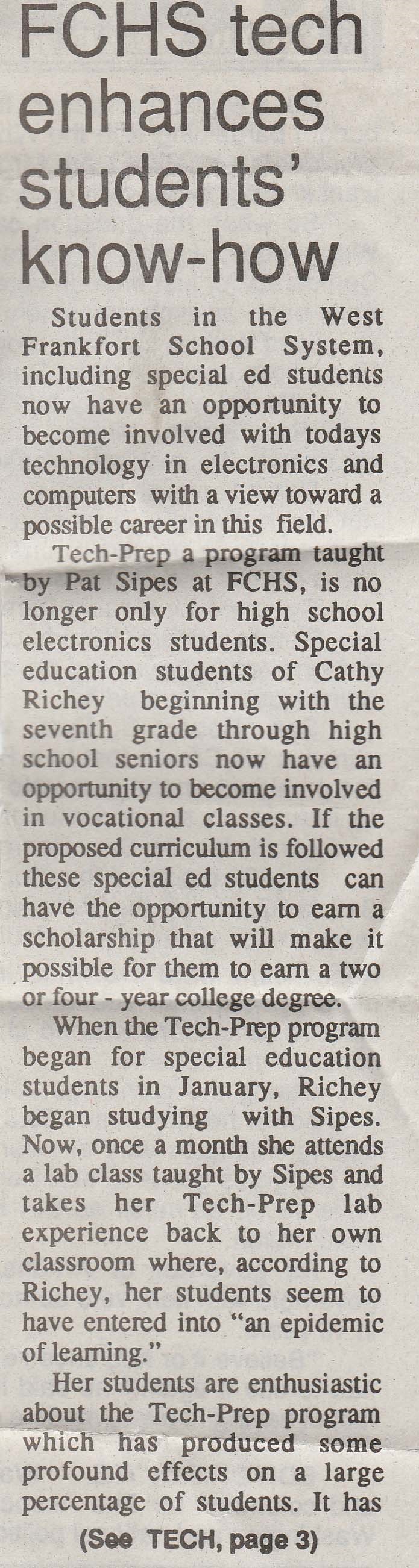

Project 44 Cathey Richey class